Principal 12 Indústrias de transformação de produtos biodegradáveis I

Sustainable solutions have become essential in 2025 as industries face mounting pressure to reduce environmental harm. The Growing Demand for Biodegradable Products reflects a shift toward sustainable living, with biodegradable startups and established companies like BASF leading innovation. Collaborations between universities and businesses drive new sustainable materials, while regulations push industries to adopt sustainable practices. The Americas biodegradable plastic market reached $2.04 bilhão em 2024, with packaging holding over half the market share. Biodegradable products now shape sectors from healthcare to agriculture, offering real benefits for those seeking sustainable and biodegradable alternatives.

Takeaways -chave

Biodegradable products help reduce pollution and support a cleaner environment across many industries like packaging, Assistência médica, and agriculture.

Materials like mushroom, alga, PLA, and PHA offer strong, eco-friendly alternatives that break down safely and quickly after use.

Growing consumer demand and stricter laws push companies to adopt sustainable products, making biodegradable options more common and affordable.

Certifications and clear labels help buyers trust that products are truly biodegradable and meet high environmental standards.

Businesses that use biodegradable products improve their sustainability, lower waste, and prepare for a greener future.

Biodegradable Packaging

Materiais

Biodegradable packaging uses a range of biodegradable materials that break down safely in the environment. As empresas agora usam mushroom-based, alga, PLA (ácido polilático), and PHA (polyhydroxyalkanoates) for eco-friendly product packaging. Mushroom-based packaging grows from agricultural waste and mycelium, forming strong, compostable shapes. Seaweed-based packaging comes from renewable sea plants and dissolves in water. PLA and PHA are plant-based plastics that offer strength and flexibility. Leading companies like TIPA, Amcor, Mundos, Tetra Pak, and Ecovative Design drive packaging innovations with these materials. The global biodegradable packaging market is projected to reach $140.6 bilhão por 2029, showing strong growth as more businesses choose sustainable packaging.

Benefits

Biodegradable packaging offers many benefits for people and the planet. It reduces landfill waste and helps fight plastic pollution, which caused $600 billion in social and economic costs by 2023. Biodegradable materials decompose in 60 para 180 dias, depending on conditions, and support composting and waste management. Modern eco-friendly product packaging matches or exceeds traditional packaging in strength, resistência ao calor, and safety. Consumer surveys show 85% satisfaction with biodegradable packaging, and a global quick-service restaurant chain cut landfill waste by 47% after switching to eco-friendly packaging. Certifications like EN13432 and ASTM D6400 ensure high standards for compostability and performance.

Aplicativos

Biodegradable packaging serves many industries. Food packaging leads the way, as people prefer natural and organic products. As empresas usam eco-friendly product packaging for trays, films, and disposable cutlery. The technology also supports shipping, varejo, and personal care products. Major brands like Unilever and Nestlé plan to use only recyclable, compostável, or biodegradable packaging by 2025. Biodegradable packaging helps businesses meet climate goals and respond to consumer demand. As more organizations rank climate change as a top concern, the use of biodegradable materials in eco-friendly product packaging continues to rise worldwide.

Compostable Food Ware

Types

Compostable food ware includes plates, xícaras, utensílios, straws, and containers made from compostable materials. These products use plant-based PLA, molded fiber, and other biodegradable sources. Compostable materials like PLA come from fermented plant starch, often corn, and serve as an alternative to petroleum-based plastics. Companies design compostable food ware to be strong enough for food service but to break down quickly in commercial composting facilities. Standards such as ASTM D6400 and EN13432 ensure that compostable products meet strict requirements for biodegradation, disintegration, and eco-toxicity. Certification programs like BPI and GreenCircle® help buyers identify safe and effective compostable options. Many brands now offer PFAS-free compostable food ware, which avoids harmful chemicals and supports safe, sustainable food packaging.

Aspecto | Descrição |

|---|---|

Tipo de material | Plant-based PLA, molded fiber, and other biodegradable sources |

Compostability Standards | ASTM D6400 (US), EN13432 (Europa) |

Durabilidade | Strong for food use, breaks down in commercial composting |

Certificação | BPI, GreenCircle® |

Industry Use

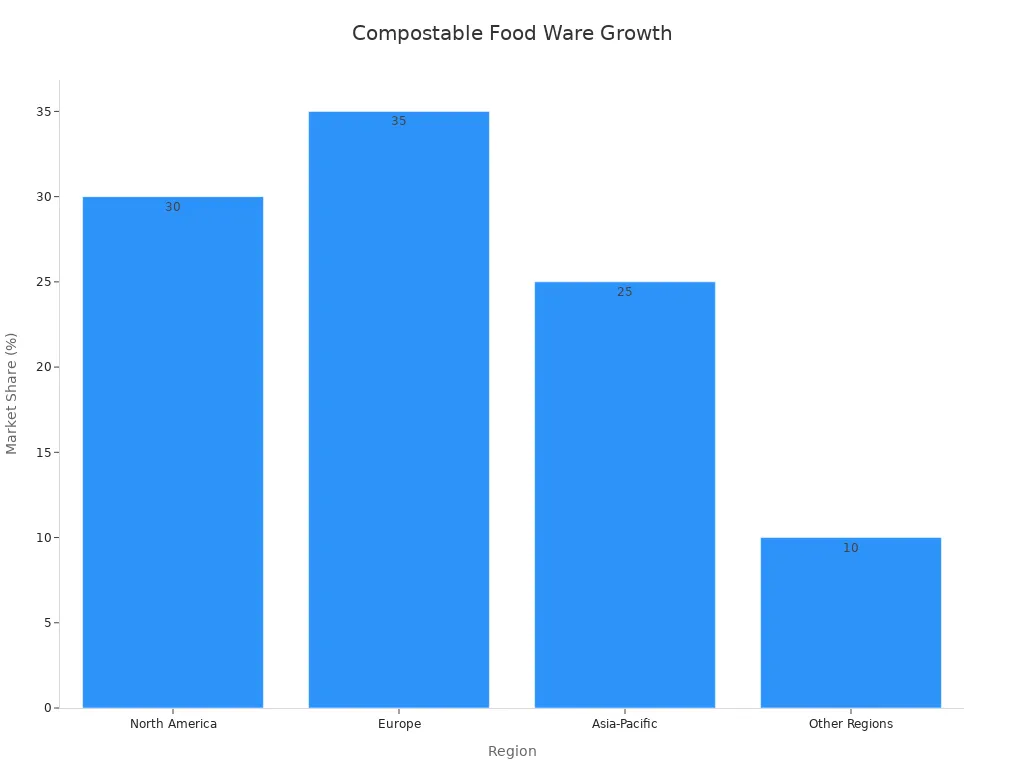

Many industries now use compostable food ware to meet new regulations and consumer demand for sustainable food packaging. Quick-service restaurants, catering services, retail chains, and food delivery companies have switched to compostable options. The European Union, California, and India have passed laws that ban single-use plastics and require compostable materials in packaging. Companies like Eco-Products, Vegware, and BioPak lead the market with new products and partnerships. The compostable food ware market is growing fast, with a projected value of $32 bilhão por 2035 and a 4.5% annual growth rate. North America holds 30% do mercado, Europa 35%, and Asia-Pacific 25%. The chart below shows the regional market share for compostable food ware.

Urbanization and the rise of online food delivery have increased the need for sustainable food packaging. Compostable food ware helps reduce landfill waste and supports a shift toward biodegradable and compostable solutions in the food industry.

Biodegradable Textiles

Materiais

Biodegradable textiles use natural and bioengineered fibers that break down safely in the environment. Many companies now choose organic cotton, hemp, and bamboo because these fibers decompose faster than synthetic ones. New fabrics made from mushroom mycelium and algae also enter the market. These materials need less water and energy to produce, which helps lower the carbon footprint. Brands like MycoWorks and Bolt Threads create mycelium-based leathers and other innovative fabrics.

Organic cotton, hemp, and bamboo break down quickly.

Mushroom mycelium and algae-based fabrics use fewer resources.

These textiles help reduce water and chemical use.

Microbial and bioengineered textiles grow as the fastest segment.

Some challenges remain, such as cost and durability, but new technology helps solve these problems.

Impacto no mercado

The biodegradable textiles market grows quickly as more people care about the environment. Fashion brands and textile makers look for sustainable options to meet new rules and consumer demand. The table below shows key facts about the market:

Aspecto | Detalhes |

|---|---|

Market Size (2025) | |

Forecast (2030) | USD 81.31 bilhão |

Cagr (2025-2030) | 8.5% |

Plant-based Fibers Share (2024) | 63.9% |

Fastest Growing Segment | Microbial/bioengineered textiles |

Leading Companies | NatureWorks LLC, BASF SE, MycoWorks, Bolt Threads |

Regional Leader (2024) | Asia Pacific (47.3% revenue share) |

Key Developments | BASF’s Loopamid jacket, MycoWorks’ mycelium plant |

Observação: Market drivers include environmental awareness, new laws, and the fashion industry’s shift to sustainability. Partnerships and product launches, such as DuPont Biomaterials’ collaborations and Giotex’s Biofa fabrics, show real progress. Case studies highlight how biodegradable textiles help reduce waste and support a circular economy.

Plant-Based Bioplastics

PLA and PHA

PLA and PHA are two leading plant-based materials changing the world of biodegradable plastics. PLA, or polylactic acid, comes from renewable resources like corn starch or sugarcane. It stands out as the most used plant-based plastic because it is biodegradable, compostável, e econômico. PLA works well in many products, such as disposable tableware, medical devices, 3D impressão, and plant-based packaging. PHA, or polyhydroxyalkanoates, is made by bacteria that feed on plant sugars. This material breaks down naturally in soil and water, making it a strong choice for single-use items and packaging.

The market for PLA and PHA continues to grow. Em 2023, the market size reached USD 1.7 bilhão. Por 2024, it grew to USD 1.9 bilhão, and experts expect it to reach USD 5.1 bilhão por 2034. The annual growth rate stands at 10.2%. Companies like NatureWorks LLC, Total Corbion PLA, and Danimer Scientific lead innovation in this field. New investments, such as a PLA plant with a 75,000-ton capacity, show strong industry support. Recent product launches include biodegradable bottle caps made from PHA.

Atributo | Valor |

|---|---|

Market Size (2023) | USD 1.7 bilhão |

Estimated Market Size (2024) | USD 1.9 bilhão |

Projected Market Size (2034) | USD 5.1 bilhão |

Cagr (2024 para 2034) | 10.2% |

Industry Trends

O plant-based bioplastics market is growing quickly. Consumers want more sustainable products, and companies respond by using plant-based packaging in food, bebida, e setores de varejo. Strict environmental rules in North America and Europe push businesses to switch to biodegradable solutions. O packaging industry uses the most plant-based materials, helping reduce fossil plastic use.

Observação: Technological advances, such as biocomposites from barley and lignin-based plastics, help create new plant-based products. These innovations support a circular economy and lower the carbon footprint.

Regional growth remains strong in North America, Europa, and Asia Pacific. Policies like the European Green Deal and government programs in Asia encourage more companies to use plant-based packaging. Challenges such as raw material supply and production costs exist, but partnerships and research centers help solve these problems. The global biodegradable plastics market reached USD 5.92 bilhão em 2024 and could grow to USD 10.04 bilhão por 2030. Plant-based bioplastics now play a key role in making industries more sustainable.

Mushroom Packaging

Tecnologia

Mushroom packaging uses mycelium, the root structure of mushrooms, to create strong and eco-friendly materials. Companies grow mycelium on agricultural waste, forming custom shapes that fit products. Automation in mushroom processing now streamlines production, making it faster and more efficient. Ecovative’s Mycelium Foundry uses advanced biotechnology and a large biological library to improve the properties of mushroom materials. Vertical growth methods save space and help scale up production. Material engineering has made mushroom packaging stronger, more durable, and water-resistant, so it can compete with Styrofoam. Major brands like Ikea, Lush Cosmetics, and Crate and Barrel use mushroom packaging for shipping and product protection. These companies show that mushroom packaging works well at a commercial level. The process uses less energy and relies on renewable resources, which supports a sustainable future.

Recent scientific reviews show that automation and new techniques have improved the quality and volume of mushroom packaging. These changes help the industry meet growing demand and support the shift to biodegradable solutions.

Benefits

Mushroom packaging offers many environmental and business benefits. It is biodegradable and compostable, breaking down quickly after use. This packaging uses agricultural waste, which supports a circular economy and reduces landfill waste. Mushroom packaging provides a sustainable alternative to plastic and foam, helping to lower plastic pollution and carbon emissions. The market for mushroom packaging grows as more people and companies want eco-friendly options. Regulatory support and government programs encourage businesses to switch to biodegradable packaging. Mushroom packaging works for electronics, Cosméticos, and food products because it is strong and versatile. Ongoing research improves its durability and adaptability, making it suitable for more industries. Consumer demand for sustainable packaging continues to rise, driving further adoption.

Mushroom packaging helps reduce waste and supports environmental goals. Research shows that controlling humidity and gas levels in packaging can keep mushrooms fresh for up to 18 dias, which reduces food waste and improves supply chain sustainability.

Seaweed Packaging

Decomposition

Seaweed packaging breaks down quickly in natural environments. Microorganisms in soil and water can digest seaweed-based materials, turning them into harmless substances. This process leaves no harmful microplastics behind. Seaweed packaging can even be edible, so it does not add to landfill waste. People can compost it at home or in industrial facilities. Seaweed contains special sugars called polysaccharides. These sugars help create films and containers that are strong but still biodegradable. Some types of seaweed also have antimicrobial properties, which can keep food fresh for longer. Unlike traditional plastics, seaweed packaging does not need fossil fuels for production. This reduces pollution and helps protect the planet.

Redução de resíduos

Seaweed packaging offers a new way to cut down on plastic waste. It uses seaweed, um fast-growing marine plant that needs little freshwater or land. Seaweed farms can even help fight climate change by absorbing carbon dioxide from the air. The production of seaweed packaging avoids the use of fossil fuels, which lowers resource depletion and environmental harm. Seaweed packaging is both biodegradable and compostable, so it does not stay in the environment for years. People can eat it, compost it, or let it break down naturally. This stops the cycle of plastic waste that often ends up in landfills or oceans. While some challenges remain in making seaweed packaging stronger and cheaper, research and new products show strong potential for reducing plastic pollution.

Seaweed packaging stands out as a sustainable alternative. It helps lower contamination in soil, água, and air, and supports a cleaner future for everyone.

Biodegradable Agricultural Films

Crop Protection

Farmers use biodegradable agricultural films to protect crops and improve yields. These films cover the soil, keeping moisture in and stopping weeds from growing. Research shows that biodegradable mulch films can increase total crop yield by 15–31% compared to bare soil. Farmers also see a 30% rise in marketable yield, which means more crops reach stores in good condition. The films help save water by reducing seasonal irrigation needs by about 8%. Water productivity improves by up to 36%, so farmers use resources more wisely. Biodegradable films also lower manual weeding costs, making farming more efficient. Earthworms in the soil help these films break down faster, which boosts soil health and keeps the environment safe for plants and animals.

Impacto ambiental

Biodegradable agricultural films offer many benefits for the environment. Unlike traditional plastic films, these materials decompose after use and do not leave harmful residues. Studies show that biodegradable mulch films reduce plastic pollution and support sustainable agriculture. Eles use less energy during production and release fewer greenhouse gases. Farmers in Asia Pacific, especially in China and India, use these films widely because of strict environmental rules and bans on regular plastics. The market for biodegradable films reached $1.0 bilhão em 2021 and could grow to $1.4 bilhão por 2026. These films use materials like PLA, starch blends, and PHA, which break down safely in the environment. The films also improve soil health by supporting earthworm activity and microbial diversity. This process helps nutrients return to the soil, making it richer for future crops.

Beneficiar | Impact on Agriculture and Environment |

|---|---|

Crop Yield | Increased by up to 31% |

Uso de água | Reduced irrigation by 8% |

Soil Health | Improved by faster film breakdown |

Pollution | Lower plastic waste and greenhouse emissions |

Economic Return | Net returns increased by up to 40% |

Biodegradable agricultural films help farmers grow more food while protecting the environment. These films support a cleaner, healthier future for both people and nature.

Sustainable Personal Care

Product Types

Sustainable personal care products now cover a wide range of daily essentials. Many brands offer biodegradable toothbrushes, cotton swabs, and facial wipes. These items break down safely after use, helping to reduce landfill waste. Skincare leads the market, with creams and cleansers made from natural and organic ingredients. Companies also create biodegradable packaging for shampoos, conditioners, and lotions. Some brands use refillable containers to cut down on single-use plastics. Haircare, bath, shower, and oral care products now often feature eco-friendly formulas and packaging. Major industry players like L’Oréal, Unilever, and Colgate Palmolive invest in research to develop new biodegradable and plant-based solutions. The table below highlights key market insights:

Segment | Entendimento |

|---|---|

Organic Market | Valued at $28.3B in 2021, projected to reach $74B by 2031 (Cagr 9.8%) |

Skincare | Growing at 9.2% Cagr, driven by demand for natural ingredients |

Online Retail | Expected to reach $33B by 2031 due to e-commerce growth |

Regional Trends | North America leads; Asia-Pacific grows fastest |

Dica: Choosing biodegradable and eco-friendly personal care products helps protect the environment and supports a healthier lifestyle.

Consumer Trends

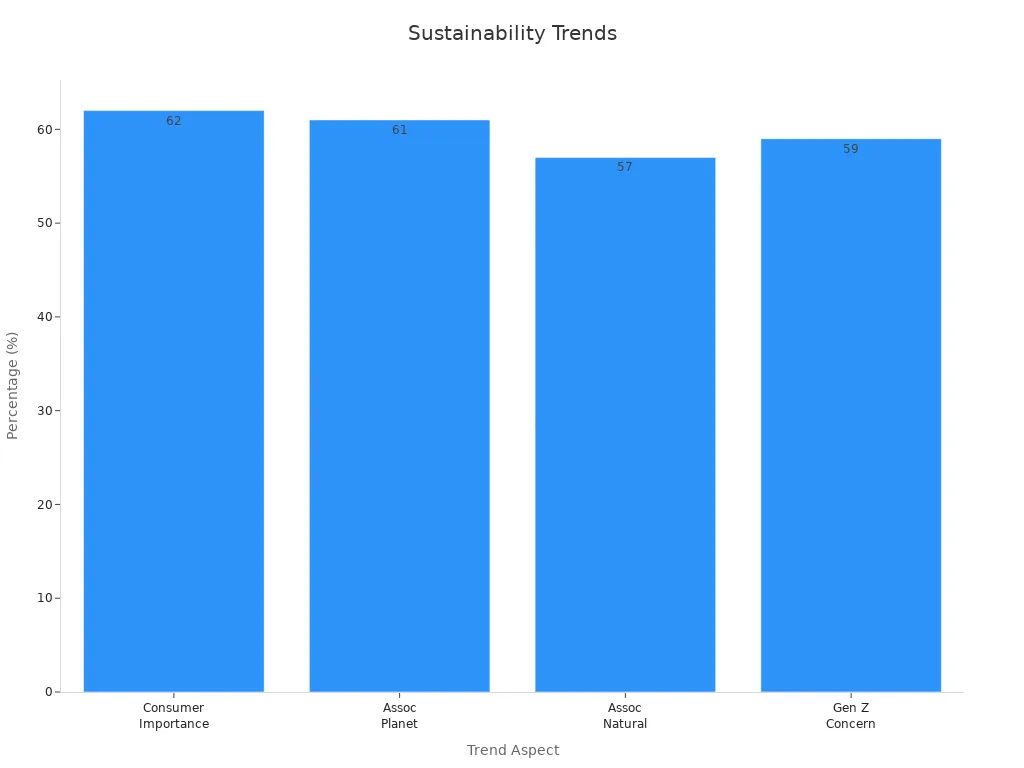

Consumers show a strong preference for sustainable personal care. Recent surveys reveal that 62% of shoppers now consider sustainability more important than two years ago. Many people look for cruelty-free, compostável, and plastic-free options. Dollar sales for cruelty-free products rose by 18.1%, while compostable products grew by 30.9%. Searches for refillable packaging increased by 64%. Gen Z, ages 15 para 27, shows high interest in sustainability, com 59% caring about eco-friendly personal care. No entanto, 56% of this group says higher prices make it harder to buy these products.

Products with environmental, social, and governance (ESG) claims grew 28% over five years. Both new and established brands see sales growth when they focus on sustainability. Online shopping now plays a big role, with more people buying biodegradable and eco-friendly products through e-commerce platforms. As awareness grows, companies respond with more ethical supply chains and sustainable packaging.

Biodegradable Medical Supplies

Inovações

Medical technology companies now focus on creating biodegradable supplies that help both patients and the environment. O European medical industry invests in new materials that meet strict safety rules and lower chemical risks. Companies work to improve product performance and make manufacturing easier. They use new-generation biodegradable polymers and composites that last longer and cost less. These materials break down safely after use, which helps reduce medical waste.

Companies use 3D printing and nanotechnology to make complex medical devices from biodegradable materials.

New manufacturing methods help lower costs and allow for mass production.

Major companies like Medtronic, Stryker, and Boston Scientific invest in research to develop better biodegradable products.

Recent breakthroughs include a flexible balloon implant for drug delivery and a new way to recycle plastics into biodegradable polymers.

Governments and the public support these changes because they want safer and greener healthcare.

These innovations help solve old problems, such as weak materials and slow breakdown rates. Agora, biodegradable medical supplies can work well in hospitals and clinics.

Healthcare Use

Hospitals and clinics use biodegradable medical supplies in many ways. These supplies include stents, heart valves, surgical tools, wound dressings, e embalagem. Polylactic acid (PLA) leads the market, making up over 40% of revenue in 2023. Other materials include polyglycolic acid, polycaprolactone, PHAs, and cellulose. Biodegradable supplies help lower infection risks and make patients more comfortable. They also support recycling and composting in healthcare.

Categoria | Detalhes & Examples |

|---|---|

Material Types | PLA, polyglycolic acid, polycaprolactone, PHAs, cellulose |

Medical Applications | Stents, heart valves, implants, wound dressings, surgical tools |

End Users | Hospitals, clinics, ambulatory surgical centers |

Regional Market Leaders | América do Norte, Europa, Asia-Pacific |

Market Size & Growth | |

Benefits | Lower infection risk, patient comfort, Reciclabalidade, compostabilidade |

Hospitals use most biodegradable supplies because they need safe, single-use items for surgeries and patient care. North America leads the market, but Asia-Pacific grows fastest due to rising healthcare needs. As more people want eco-friendly options, the use of biodegradable medical supplies will keep rising.

Eco-Friendly Cleaning Products

Ingredients

Eco-friendly cleaning products use natural and biodegradable ingredients to keep homes and workplaces safe. Many companies choose plant-based surfactants, essential oils, and minerals instead of harsh chemicals. These ingredients break down easily in the environment and do not harm water or soil. Some brands use coconut oil, citric acid, and baking soda to clean surfaces. Others add vinegar or lemon for extra cleaning power. Companies also focus on eco-friendly product packaging, using bottles made from recycled materials or refillable containers. Unilever plans to replace fossil fuel-based chemicals with renewable carbon sources by 2030. This change could lower the carbon impact of their products by up to 20%. Nouryon invests in biodegradable chelates to meet the growing demand for safe cleaning solutions. Market research shows that the global green and bio polyols market will grow from $4.52 bilhão em 2022 para $9.35 bilhão por 2030, with a CAGR of 9.5%. Verified Market Reports confirm this trend by collecting data from industry experts and company reports. These efforts help make cleaning safer for people and the planet.

Market Growth

The market for eco-friendly cleaning products is expanding quickly. Several factors drive this growth:

Rising consumer awareness about the health and environmental risks of traditional cleaners.

More green certifications and eco-labels increase trust in eco-friendly brands.

Wider availability in stores and online makes it easier for people to buy these products.

Companies use renewable resources and eco-friendly product packaging to attract customers.

Innovations like concentrated formulas, plant-based ingredients, and refillable packaging match consumer preferences.

Governments enforce stricter rules on toxic chemicals and encourage biodegradable ingredients and recyclable packaging.

North America and Europe lead the market due to strong regulations and established brands. Asia-Pacific is growing fast as more people move to cities and care about the environment.

Eco-friendly cleaning products now play a key role in reducing pollution and supporting a healthier lifestyle. Companies that use biodegradable ingredients and eco-friendly product packaging help protect the planet for future generations.

Biodegradable Electronics

Components

Biodegradable electronics use special materials that break down safely after their useful life. Companies design these components with the environment in mind. Many new devices use coatings made from cellulose, silk, and other non-toxic substances. These coatings help reduce toxic electronic waste. Some engineers use self-healing polymers and adaptive coatings to make devices last longer and stay safe for people and nature. Medical devices and sensors often use these biodegradable materials because they need to be safe inside the body or in the environment. Panasonic, Samsung, and PragmatIC Semiconductor lead the way by creating new biodegradable smartphone parts and sensors for farms. These innovations show how technology can protect the planet.

Observação: Certifications and standards help make sure each component meets strict environmental rules. Green inventory management and demand forecasting also help reduce waste and support eco-friendly sourcing.

Industry Adoption

The electronics industry now moves toward sustainable practices. North America leads this change with strong research and government support. Companies work together at events like the Sustainable Manufacturing Expo. Scientists, manufacturers, and policymakers share ideas and set new standards for biodegradable electronics. Many businesses use eco-friendly packaging and carbon-offsetting to lower their impact. They also teach customers about the benefits of biodegradable products. Circular economy programs, such as take-back and refurbishment, help extend the life of devices. Digital tools give buyers real-time data on environmental impact, making it easier to choose green options. Marketing teams highlight these efforts to build trust and show leadership in sustainability.

Certifications and standards ensure components meet environmental criteria.

Circular economy programs extend product life cycles.

Digital tools and transparency help customers make informed choices.

Strategic alliances foster innovation and best practices.

Market data shows that medical devices and conductive polymers grow quickly because of their sustainability benefits. Government policies and consumer education drive more companies to adopt biodegradable electronics. As more people learn about the environmental impact, the demand for these products continues to rise.

Compostable Shipping Materials

Soluções de embalagem

Compostable shipping materials are changing the way companies approach packaging solutions. Many businesses now use compostable mailers, padded envelopes, and box fillers made from plant-based sources. These packaging solutions break down safely after use, leaving no harmful waste behind. Companies choose compostable packaging because it reduces the carbon footprint. Production uses less energy than traditional plastics. Water-resistant compostable materials protect goods during shipping, keeping items safe from damage.

Compostable packaging solutions help brands show their commitment to the environment.

Proper disposal and composting are important for the full benefits. Consumer education plays a key role.

Composting these materials creates nutrient-rich fertilizer, which improves soil quality and supports healthy ecosystems.

Advances in material science have made compostable packaging solutions more affordable for businesses.

Growing consumer awareness and stricter rules against single-use plastics drive demand for compostable packaging. E-commerce growth increases the need for sustainable packaging solutions. Companies like Amcor and others invest in new biodegradable and compostable packaging to meet these needs.

Logistics Impact

Compostable shipping materials also improve logistics. Companies use logistics optimization tools to find shorter delivery routes and reduce fuel emissions. Packaging solutions that fit products better help lower shipping costs and carbon output. Waste management programs that support recycling and composting make it easier for businesses to adopt these materials.

Reduced carbon footprint comes from both the packaging and the way it is shipped.

Compostable packaging solutions help companies meet corporate social responsibility goals.

Government actions and global partnerships encourage more use of biodegradable and compostable packaging.

Industry mergers highlight the growing importance of sustainable packaging solutions.

Compostable shipping materials offer clear benefits for the environment and business. They support a cleaner supply chain and help companies build trust with customers.

Growing Demand for Biodegradable Products

Market Drivers

The growing demand for biodegradable products shapes many industries in 2025. People want sustainable solutions that protect the planet. Companies respond by using sustainable materials sourcing and Embalagens ecológicas. Urbanization increases the need for cost-effective recycled packaging. Technology improves how manufacturers make biodegradable goods, making them stronger and more affordable. Asia-Pacific leads the market because of environmental awareness, urban growth, and higher incomes.

Market Segment/Region | Market Size (USD Billion) | Cagr (%) | Key Drivers and Applications |

|---|---|---|---|

Global Biodegradable Plastics | 21.3 | Environmental awareness, packaging demand, strict regulations in US, Europa, Japão | |

Asia Pacific Biodegradable Plastics | 6.50 (2029) | 23.4 | Low-cost raw materials, government support, demand in packaging, consumer goods, agriculture, textiles |

North America Biodegradable Plastics | 9.6 (2022-2030) | Urbanization, renewability of bio-based products, flexible packaging, medical sectors |

People now prefer sustainable brands and products with biodegradable ingredients. Many accept higher prices for sustainable goods that match their values. Peer reviews and influencer support guide buying choices. Brands use data to understand what customers want. The circular economy grows as companies design products for reuse and recycling.

Regulatory Trends

Regulations play a big role in the growing demand for biodegradable products. Governments pass laws to limit single-use plastics and encourage sustainable packaging. The EU Plastic Directive and similar rules in other regions push companies to use recycled and biodegradable materials. These changes help reduce pollution and support a circular economy.

Consumers want transparency and honesty from sustainable brands. They look for packaging that is safe for the environment and visually appealing. Social pressure and community action lead to bans on plastic packaging. People support paper or carton alternatives. The market for biodegradable products reached $7.8 bilhão em 2024 and could grow to $18.5 bilhão por 2033. This growth comes from new laws and changing consumer habits. Even with higher costs and limited disposal options, investment in sustainable solutions keeps rising. Companies that focus on sustainability and sustainable materials sourcing build trust and lead the way in the global market.

Sustainable Packaging Trends

High-Barrier Materials

High-barrier materials are changing the world of packaging. These materials block gases, UV light, and moisture, which helps keep food and medicine fresh. Many companies now use bio-based polymers and compostable coatings in biodegradable packaging. These new materials protect products from spoilage and reduce waste. Mono-material barrier films make recycling easier because they use only one type of material. This supports the circular economy and helps create more recyclable packaging.

Recent studies show that high-barrier materials extend shelf life and improve product safety. Por exemplo, antimicrobial properties in packaging stop bacteria from growing. Automation and artificial intelligence help companies design better packaging and detect defects quickly. These advances lower costs and improve efficiency. Regulatory rules in North America, Ásia, and Europe push companies to use safer, reciclável, and bio-based barrier materials. Zotefoams’ ReZorce is one example of a sustainable design that won industry awards.

High-barrier materials in biodegradable packaging help meet market goals for sustainability and product protection.

Smart Packaging

Smart packaging uses technology to make products safer and more convenient. Companies add sensors, Códigos QR, and smart labels to packaging. These tools track temperature, humidity, and freshness in real time. Por exemplo, sensors can show if food stayed cold during shipping. QR codes let shoppers scan packaging to learn about the product or see if it is real.

Nanotechnology improves the barrier properties and durability of biodegradable packaging. Some smart packaging uses oxygen scavengers and moisture control to keep food fresh longer. Biometric features, like unique codes or holograms, help stop food fraud. Smart packaging also supports recycling by using labels that tell people how to dispose of the packaging.

Smart packaging improves food safety and reduces waste.

Real-time monitoring helps companies manage supply chains better.

Interactive features make shopping more fun and informative.

Sustainable packaging trends show that companies want to use more biodegradable packaging and recyclable packaging. These changes help protect the environment and meet consumer demand for safer, greener products.

Adopting Sustainable Products

Implementation Steps

Organizations that want to adopt sustainable products can follow a clear process. Primeiro, eles define their sustainability commitments and set a purpose that fits their business needs. They align with vendors and stakeholders to make sure everyone shares the same values. Setting realistic goals and timelines helps teams move forward step by step. Companies often use supply chain sustainability initiatives, such as codes of conduct and audits, to promote sustainable practices among suppliers.

Dica: Clear communication with employees and regular feedback sessions help everyone understand new policies and track progress.

A successful approach includes these steps:

Define sustainability goals and purpose.

Align with vendors and stakeholders.

Set realistic timelines for adopting sustainable products.

Communicate policies clearly to all employees.

Use supply chain sustainability initiatives.

Track progress and adjust strategies as needed.

Research shows that companies using these steps see better performance, custos mais baixos, and reduced risks. Environmental innovations from adopting sustainable products often lead to value creation and improved competitiveness.

Overcoming Barriers

Many businesses face challenges when adopting sustainable products. Small and medium-sized enterprises (SMEs) often struggle with limited knowledge, small workforces, and financial constraints. They may also focus on short-term gains or feel unsure about the payback period. Lack of stakeholder awareness can slow progress.

Barriers for SMEs | Opportunities for SMEs |

|---|---|

Regulatory mandates | |

Financial constraints | Management commitment |

Short-term focus | Supplier relationships |

Skepticism about payback periods | Green product innovation |

Lack of stakeholder awareness | Community and investor support |

Companies can overcome these barriers by investing in training, building strong supplier relationships, and seeking community support. Management commitment and regulatory mandates also help drive change. Adopting Environmental Management Systems, such as ISO 14001, reduces environmental impact and improves productivity. When organizations focus on both internal and external factors, they find more success with sustainable products.

Verifying Biodegradable Claims

Certificações

Certifications help buyers trust that a product is truly biodegradable or sustainable. Third-party organizations like the Biodegradable Products Institute (BPI), TÜV Áustria, EcoCert, and Fairtrade International check products for honesty and safety. These groups review lab data and make sure products meet rules such as the FTC Green Guides. The Green Guides require that products labeled as biodegradable must break down within one year. Certification marks often appear on packaging or labels. Shoppers can also check company websites or certification bodies for more details.

The table below lists important certifications and standards for biodegradable and sustainable products:

Certificação | Região | Padrão | Key Criteria |

|---|---|---|---|

OK Compost Industrial | Global | EN 13432 | Industrial composting; ≥ 90% biodegradation in 6 meses; no toxic residues |

OK Compost Home | Global | TÜV Áustria | Home composting; ≥ 90% biodegradation in 12 meses; ≤ 10% disintegration after 6 meses |

OK Biodegradable Soil | Global | TÜV Áustria | Soil biodegradation in 24 meses; no toxic residues |

OK Biodegradable Water | Global | TÜV Áustria | Freshwater biodegradation in 56 dias; no toxic residues |

OK Biodegradable Marine | Global | TÜV Áustria | Marine biodegradation in 60 dias; no toxic residues |

EN 13432 | EU, UK | EN 13432 | Embalagem; ≥ 90% biodegradation in 6 meses; Compostagem industrial |

EN 14995 | EU, UK | EN 14995 | All plastics; ≥ 90% biodegradation in 6 meses; Compostagem industrial |

ASTM D6400 | US | ASTM D6400 | ≥ 60% biodegradation in 180 dias; Compostagem industrial |

Certificação BPI | US | ASTM D6400/D6868 | Third-party verification; Compostagem industrial |

Other trusted labels include USDA Organic, Energy Star, and Forest Stewardship Council (FSC). Each one checks for different environmental standards.

Buyer Tips

Buyers can take steps to avoid greenwashing and make sure claims are real:

Look for trusted certifications like BPI, TÜV Áustria, USDA Organic, Energy Star, or FSC.

Check for certification marks on packaging or scan QR codes for more information.

Use digital tools such as GreenGuide Scanner or EcoVerify to check labels.

Read product details on company or certification websites.

Watch out for vague claims like “eco-friendly” without proof.

Build a list of brands with a good track record for sustainability.

Report false claims to consumer protection agencies.

Dica: Third-party verification often includes lab testing, on-site audits, and regular checks. This process helps keep products honest and safe for the environment.

By following these steps, buyers can choose products that truly support a cleaner planet.

Biodegradable products reshape industries in 2025 by reducing pollution and supporting sustainable growth.

Europe leads with strict rules and strong demand, while Asia-Pacific grows fastest as awareness rises.

Comida, Assistência médica, and personal care sectors show broad adoption.

Biodegradable plastics and starch-based materials gain market share, but innovation remains vital.

Impact Area | Result |

|---|---|

Boosts jobs and social well-being | |

Increases green innovation and support |

Businesses that adopt these solutions help the environment and prepare for a cleaner future.

Perguntas frequentes

What makes a product biodegradable?

A product is biodegradável if natural organisms like bacteria or fungi can break it down into harmless substances. These products usually return to nature within a set time, leaving no toxic residue.

How can someone check if a product is truly biodegradable?

People can look for trusted certifications such as BPI, TÜV Áustria, or EN 13432 on the label. These marks show that the product passed strict tests for biodegradability and safety.

Are biodegradable products always compostable?

Not all biodegradable products are compostable. Compostable items break down into safe compost under specific conditions. Biodegradable products may need different environments and might not create useful compost.

Why do some biodegradable products cost more?

Biodegradable products often use new materials and technology. Production costs can be higher than regular plastics. As demand grows and technology improves, prices may decrease.

Can biodegradable products go in regular trash?

Most biodegradable products work best in composting or special recycling systems. If thrown in regular trash, they may not break down properly because landfills lack air and moisture.