Комплексное руководство по упаковке PLA и устойчивому развитию

Руководство по упаковке PLA

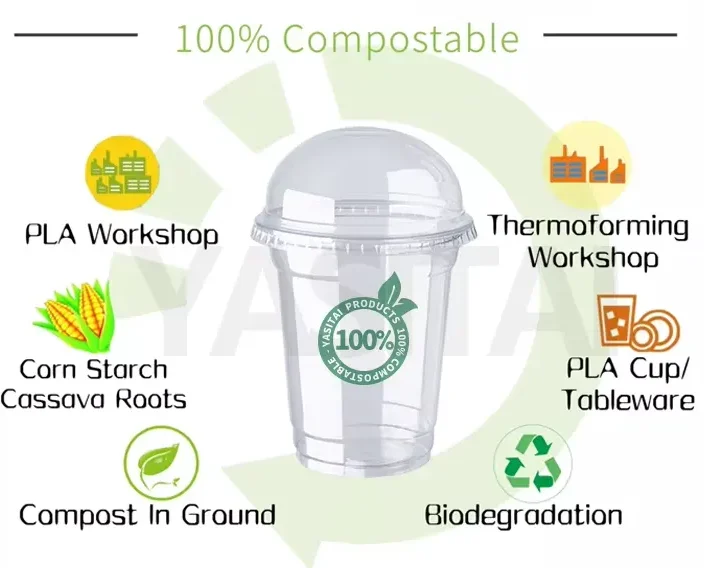

Полилактановая кислота (НОАК) производит революцию в подходе к упаковочным решениям. Мир столкнулся с серьезной пластиковой проблемой, создание 400 миллионов тонн отходов ежегодно, внедрение чашек PLA предлагает более экологичную альтернативу. В отличие от традиционных вариантов, таких как ПЭТ Кубок и Кубок ПП, PLA биоразлагаем и компостируем., разрушаться естественным путем и приносить пользу планете. Получено из возобновляемых ресурсов, таких как кукуруза и сахарный тростник., PLA более экологичен по сравнению с обычными пластиками.. Такие компании, как TotalEnergies Corbion, подчеркивают, что PLA производит 75% меньше углеродного загрязнения чем пластмассы на масляной основе. Поскольку рынок PLA быстро расширяется, растет примерно 12% каждый год, многие отрасли используют PLA для борьбы с изменением климата и удовлетворения экологических требований., особенно если учесть различия в устойчивости между ПП против ПЭТ.

Ключевые выводы

Полилактановая кислота (НОАК) зеленый вариант вместо обычного пластика. Он сделан из таких растений, как кукуруза и сахарный тростник..

PLA может разрушаться естественным путем, поэтому это помогает уменьшить количество мусора на свалках.

Использование PLA может сократить выбросы вредных газов до 63%. Это помогает бороться с глобальным потеплением.

Применение PLA 65% меньше энергии, чем производство пластмасс на нефтяной основе. Это делает жизнь планеты лучше.

Компании могут получить больше экологически чистые клиенты с использованием PLA. Многим людям нравятся продукты, которые помогают окружающей среде..

ПЛА нужно выбрасывать правильно. Лучше всего он работает при компостировании в специальных промышленных местах..

Обучение людей тому, как выбрасывать PLA, может показать заботу вашего бренда о природе..

Рынок PLA быстро растет. Возможно, это стоит $6.9 миллиард за 2031 потому что все больше людей хотят использовать экологически чистые материалы.

Что такое полимолочная кислота (НОАК) и как это сделано?

Определение и состав PLA

Полилактановая кислота (НОАК) это пластик, который разлагается естественным путем. Он сделан из таких растений, как кукуруза., сахарный тростник, или маниова. В отличие от обычного пластика из нефти, PLA использует возобновляемые материалы. Имеет длинные цепи молочной кислоты., делая его сильным и гибким. НОАК это ясно, так что это хорошо подходит для упаковки. Он также защищает продукты от влаги и воздуха.. Но, он не выдерживает сильного нагрева, поэтому он не используется для горячих блюд.

Свойство | Описание |

|---|---|

Биоразлагаемость | Быстро распадается на натуральные материалы.. |

Возобновляемый источник | Изготовлено из таких растений, как кукуруза., сахарный тростник, или маниова. |

Прочность и жесткость | Прочный и долговечный для многих целей. |

Термостойкость | Легко плавится; не подходит для жарких помещений. |

Ясность и прозрачность | Прозрачный, отлично подходит для упаковки продуктов питания и розничной торговли. |

Барьерные свойства | Защищает вещи от воздуха и влаги. |

Возможность печати | Легко печатать и получать хорошие результаты. |

Стабильность размеров | Сохраняет форму и размер с течением времени. |

Процесс производства PLA

Ферментация растительного крахмала или сахара

PLA начинается с таких растений, как кукуруза или сахарный тростник.. Эти растения ферментируются с использованием бактерий или дрожжей.. Этот процесс превращает растительный материал в молочную кислоту.. Качество молочной кислоты очень важно.. Чтобы производить хорошие продукты из PLA, он должен быть чистым..

Превращение в молочную кислоту и полимолочную кислоту

Следующий, молочная кислота очищается от всего нежелательного. Чистая молочная кислота затем превращается в PLA посредством процесса, называемого полимеризацией.. Это связывает молочную кислоту в длинные цепи.. На этом этапе используются специальные инструменты и условия.. Затем PLA охлаждают и формуют в небольшие гранулы.. Эти гранулы используются для изготовления упаковки или материалов для 3D-печати..

Шаг | Описание |

|---|---|

Ферментация | |

Purification | Cleans the lactic acid to make it pure. |

Polymerization | Links lactic acid into long chains to create PLA. |

Pelletization | Cools and shapes PLA into small pellets. |

Processing | Uses pellets to make finished products like packaging. |

Renewable Feedstocks for PLA

Corn, Сахарный тростник, and Cassava

PLA is made from plants like corn, сахарный тростник, и маниова. These plants provide the sugar or starch needed for production. Using these plants makes PLA better for the environment than oil-based plastics. Leftover parts of these plants can also be used, сокращение отходов. Например, sugarcane leftovers can help make PLA.

PLA comes from plants like corn, cassava, and sugarcane.

Leftover plant parts can be used, сокращение отходов.

Making PLA creates less pollution than regular plastics.

Life Cycle Assessments (LCAs) check how PLA affects the environment. They make sure the process avoids harmful chemicals or too much pollution.

Emerging Non-Agricultural Feedstocks

New ways to make PLA use things other than crops. These include algae, food scraps, and even carbon dioxide. Using these materials means less farmland and water are needed. Например, algae-based PLA can grow in areas where crops can’t, helping save farmland for food.

Comparison with Petroleum-Based Plastics

PLA vs PET and PP

Полилактановая кислота (НОАК) is different from plastics like ДОМАШНИЙ ПИТОМЕЦ и ПП. НОАК is made from plants, пока ДОМАШНИЙ ПИТОМЕЦ и ПП come from oil. This makes НОАК a greener option. Unlike ДОМАШНИЙ ПИТОМЕЦ, which can be recycled, НОАК is compostable. It breaks down into natural materials under certain conditions, Уменьшение отходов свалки.

Making НОАК uses less energy than making oil-based plastics. Studies show НОАК needs 65% less energy to produce. It also creates 63% fewer greenhouse gases. These facts show how НОАК helps the planet more than ДОМАШНИЙ ПИТОМЕЦ и ПП. Но НОАК has limits. It cannot handle high heat, so it’s not good for some uses where ДОМАШНИЙ ПИТОМЕЦ или ПП work better.

Environmental and Economic Advantages

Switching to НОАК helps the environment in many ways. Its production releases fewer greenhouse gases, fighting climate change. НОАК also doesn’t rely on limited oil resources. It uses fast-growing plants like corn or sugarcane, cutting oil use. Groups like the EPA и FDA support biodegradable plastics like НОАК. This shows the need for eco-friendly materials is growing.

Using НОАК also makes sense for businesses. More people care about helping the planet. Companies using НОАК can attract these customers and follow stricter rules on plastic waste. While НОАК costs more to make than ДОМАШНИЙ ПИТОМЕЦ или ПП, its benefits are worth it. Choosing НОАК supports a circular economy and shows your brand cares about sustainability.

Кончик: Teach customers how to compost НОАК. Proper disposal ensures it helps the environment.

Environmental Benefits of Polylactic Acid (НОАК)

Less Greenhouse Gas Emissions

Using Polylactic Acid (НОАК) helps lower greenhouse gas emissions. Unlike oil-based plastics, PLA is made from plants like corn. These plants take in carbon dioxide as they grow, balancing some emissions. Studies show PLA can cut emissions by up to 63%. This helps fight climate change and reduces carbon footprints worldwide.

Lifecycle assessments (LCAs) check how PLA impacts the environment. They compare PLA’s emissions to regular plastics. Results show PLA has a smaller carbon footprint. Composting PLA also keeps waste out of landfills, cutting methane gas. Methane is harmful to the planet, so reducing it is very important.

Тип доказательств | Описание |

|---|---|

Lifecycle Assessments (ДМС) | LCAs show how PLA is better for the planet than regular plastics. |

Компостируемость | Composting PLA cuts greenhouse gases equal to 42 угольные электростанции. |

Сертификация BPI | Доказывает, что PLA соответствует правилам компостирования и правильно разлагается.. |

Использует меньше энергии для изготовления

Производство PLA требует меньше энергии, чем производство пластиков на масляной основе.. В процессе используются растительные сахара., нуждающийся 65% меньше энергии, чем обычный пластик. Это экономит энергию и снижает воздействие PLA на окружающую среду.. Выбор PLA помогает экономить энергию и снижает потребность в масле..

Экономия энергии также помогает предприятиям экономить деньги. Хотя PLA стоит дороже, экономия энергии может сбалансировать затраты. Это делает PLA разумным выбором для экологически чистые компании.

Разрушается естественным образом

Лучшая особенность PLA заключается в том, что он разрушается естественным путем.. Обычный пластик служит сотни лет., но ПЛА превращается в воду, углекислый газ, и органический материал. Это помогает уменьшить количество пластиковых отходов в окружающей среде..

Правила промышленного компостирования

PLA meets strict composting rules, like those from the Biodegradable Products Institute (БПИ). These rules ensure PLA breaks down in industrial composting centers. These centers use high heat and moisture to help PLA decompose. Look for BPI labels to know if a PLA product is compostable.

Home Composting Challenges

PLA works better in industrial composting than at home. Home composting doesn’t have the right conditions for PLA to fully break down. But new ideas are improving PLA for home composting. To get the most benefits, dispose of PLA in industrial composting centers.

Contribution to the Circular Economy

Moving Away from Fossil Fuels

НОАК helps reduce the use of fossil fuels. Regular plastics are made from oil, which is limited and pollutes. НОАК comes from plants like corn and sugarcane, which grow back. Using НОАК lowers oil demand and supports a greener future.

Making НОАК fits with the idea of reusing materials. Oil-based plastics often end up as trash in landfills. Но НОАК can be composted or recycled if done properly. This cuts waste and keeps materials in use. Choosing НОАК shows you care about the planet and want less oil use.

Кончик: Pick items marked “biobased” или “компостируемый” to help reduce oil-based plastics.

Stopping Plastic Pollution

Plastic waste harms oceans and nature every year. НОАК helps because it breaks down naturally in composting conditions. Unlike regular plastics, which last for centuries, НОАК turns into water, углекислый газ, and natural material. This lowers long-term harm to the environment.

You can stop plastic pollution by throwing away НОАК the right way. Composting centers are the best places for НОАК to break down. Teach people about these options to help. When handled correctly, НОАК keeps trash out of oceans and protects animals.

Примечание: НОАК needs special conditions to break down. Support composting programs to get the most benefits from НОАК.

Challenges and Limitations of Polylactic Acid (НОАК)

Disposal and Composting Infrastructure

Limited Access to Industrial Composting Facilities

Getting rid of Polylactic Acid (НОАК) can be hard. Many areas don’t have composting centers for НОАК. These centers use high heat to break down НОАК properly. Without them, НОАК often ends up in landfills. На свалках, it doesn’t decompose as it should. This confuses people who think НОАК is always compostable. Many places still lack the right systems for НОАК disposal. This limits its positive impact on the environment.

Кончик: Look for local composting centers before buying НОАК продукты.

Methane Emissions in Landfills

Throwing НОАК into landfills can cause methane gas. Метан — сильный газ, который усугубляет изменение климата. На свалках нет подходящих условий. НОАК безопасно сломаться. Вместо, НОАК может выделять метан, поскольку гниет без воздуха. Это вредит его экологичному имиджу.. Чтобы решить эту проблему, необходимы более совершенные системы удаления отходов..

Ограничения стоимости и производительности

Более высокие производственные затраты по сравнению с обычными пластиками

Making НОАК стоит дороже, чем изготовление обычного пластика, такого как ДОМАШНИЙ ПИТОМЕЦ или ПП. Это связано с тем, что материалы на биологической основе, такие как кукуруза и сахарный тростник, стоят дороже.. Процесс изготовления НОАК также использует больше энергии и следует строгим правилам. Эти факторы делают НОАК менее доступный. Из-за этого на рынке доминируют более дешевые пластмассы на нефтяной основе..

НОАК вместо нефти используются дорогостоящие растительные материалы.

Его производство требует больше энергии и следует строгим правилам..

Высокие затраты делают его менее конкурентоспособным на рынке..

Sensitivity to Humidity and Temperature

НОАК has limits that affect how it’s used. It doesn’t handle heat well, so it can melt or warp. Например, hot liquids can ruin НОАК packaging. It also doesn’t block air or moisture as well as ДОМАШНИЙ ПИТОМЕЦ. This makes it less useful for keeping food fresh.

НОАК melts in high heat, limiting its uses.

It doesn’t block air or water as well as ДОМАШНИЙ ПИТОМЕЦ.

These issues make it less useful for some industries.

Ethical and Environmental Concerns

Impact of Agricultural Crop Use on Food Resources

Making НОАК depends on crops like corn and sugarcane. This raises concerns about using food for plastic instead of feeding people. In areas with food shortages, this can make problems worse. Using crops for НОАК also competes with farmland for growing food. This can raise food prices and hurt communities.

Land and Water Use in Crop Cultivation

Growing crops for НОАК has environmental downsides. Large farms can cause deforestation and harm wildlife. They also pollute water and reduce biodiversity. Reports show these farming practices can hurt ecosystems and nearby communities. While НОАК is better than oil-based plastics, its farming needs raise concerns about sustainability.

Примечание: Using new ideas like algae-based НОАК can lower farming impacts.

Regulatory and Standardization Issues

No Clear Federal Rules for Compostability

Many think all compostable items, like PLA, break down easily. But without clear federal rules, this isn’t always true. Compostable plastics need special conditions, like high heat and moisture, to decompose. These conditions are only found in industrial composting centers. Sadly, not all items labeled “компостируемый” meet these needs. This confuses people and makes waste management harder.

The USDA is working on new rules for compostable bioplastics. These rules could ensure PLA products meet strict composting standards. Some states already have laws for better labeling on compostable items. But without nationwide rules, there are still differences.

“Voluntary standards don’t work… Federal rules for compostability are needed to avoid conflicts.”

Countries like France are leading the way by banning single-use plastics. They aim to stop using all single-use plastic packaging by 2040. This pushes industries to use eco-friendly materials like PLA. Similar U.S. policies could grow the PLA market and cut plastic waste.

Country | Regulation Details | Effect on PLA Market |

|---|---|---|

France | Banned some single-use plastics in 2021; plans to end all single-use plastic packaging by 2040. | Encourages industries to use bioplastics like PLA to meet eco-friendly goals. |

Индия | Set rules in 2021 to ban certain single-use plastics by July 2022; required EPR for plastic waste. | Pushes industries to switch to sustainable options like PLA to follow the rules. |

Importance of Extended Producer Responsibility (EPR) Laws

EPR laws make companies responsible for their products’ entire lifecycle. This includes how they are disposed of. These laws push businesses to create better packaging and invest in composting or recycling systems. For PLA, EPR laws could help ensure proper disposal and ease the burden on consumers.

India already has EPR rules for managing plastic waste. These rules encourage industries to use alternatives like PLA. In the U.S., some states are also passing EPR laws that affect packaging choices. Federal agencies may soon release policies that could shape PLA’s future.

The USDA is working on rules for compostable bioplastics.

Some states are passing EPR laws that affect packaging.

Federal policies may soon impact the PLA market.

EPR laws can help create a system where materials like PLA are reused or composted. This reduces landfill waste and inspires new ideas for eco-friendly packaging. Supporting these laws helps build a cleaner, greener future for everyone.

Применение полилактивной кислоты (НОАК) в упаковке

Пищевая упаковка

FDA-Approved for Food Contact

Полилактановая кислота (НОАК) is safe for food packaging. А FDA approves it for food contact, ensuring safety. This means НОАК can store and transport food without harm. It’s non-toxic, so it protects food while keeping it safe.

Attribute | Доказательство |

|---|---|

FDA Approval | НОАК is approved by the FDA for food packaging. |

Безопасность | НОАК is safe for food contact and storage. |

Температурная устойчивость | Handles heat up to 110°C, good for hot food. |

Barrier Properties | Keeps food fresh with strong oxygen barrier properties. |

Приложения | Used for cups, plates, bowls, and cutlery. |

Popularity | Common for fresh produce, meals, and drinks. |

Antibacterial Properties | Added agents improve food safety and shelf life. |

Versatile and Moldable for Various Needs

НОАК is flexible and works for many packaging needs. It’s used for cups, plates, bowls, and even cutlery. Its shape can be adjusted to fit different uses. НОАК also keeps food fresh by blocking oxygen. It’s great for fresh produce, meals, and drinks. This makes НОАК a practical and eco-friendly choice.

НОАК is safe for food contact, approved by the FDA.

It handles heat up to 110°C, good for hot foods.

Common uses include cups, plates, and clamshell containers.

It keeps food fresh with strong oxygen barriers.

Healthcare and Pharmaceutical Uses

Antimicrobial Additives for Contamination Prevention

In healthcare, НОАК can stop contamination with special additives. These additives block germs, making НОАК great for medical tools. It’s used in surgical tools and disposable healthcare items. Its germ-fighting properties help lower infection risks.

Application Area | Antimicrobial Properties | Additional Notes |

|---|---|---|

Healthcare and Pharmaceutical | НОАК can include additives to stop germ growth. | Used in medical tools and disposable healthcare items. |

Bioactive Ingredients | Natural agents like plant extracts can be added. | Meets demand for eco-friendly healthcare solutions. |

Innovations | New coatings improve НОАК’s germ-blocking ability. | Makes НОАК better for reducing contamination risks. |

Applications in Medical Devices

НОАК works well for medical tools because it’s safe for the body. It’s used in stitches, drug delivery systems, and disposable tools. Natural ingredients like plant oils can be added to make it eco-friendly. New coatings also make НОАК better at stopping germs.

Consumer Goods and Retail

Biodegradable Options for Everyday Products

НОАК breaks down naturally, making it great for daily items. It’s used in shopping bags, посуда, и упаковка. Its ability to decompose appeals to eco-conscious buyers. Choosing НОАК helps reduce plastic waste and supports sustainability.

Customizable Solutions for Branding

НОАК packaging can be customized for businesses. Its clear design lets customers see the product inside. You can print on it, making it great for branding. This mix of style and function makes НОАК popular for retail packaging.

Кончик: Использовать НОАК packaging to show your eco-friendly efforts and attract green-minded customers.

Innovations in PLA Packaging

Enhanced Barrier Properties

New improvements make НОАК packaging better at protecting items. Old НОАК had trouble blocking air and water. Сейчас, scientists use nanocomposites and layered films to fix this. These changes help keep food fresh longer. Например, snacks stay tasty and safe with these materials.

Nanocomposites add tiny particles to strengthen НОАК. These particles stop air and water from getting through. Layered films mix different materials to make НОАК tougher. Both methods improve НОАК for food and drink packaging. These upgrades make НОАК as good as regular plastics but eco-friendly.

Кончик: Выбирать НОАК packaging with better barrier features. It’s great for food and sensitive items.

Integration of Bioactive Ingredients

Adding natural ingredients is another cool change for НОАК. Plant extracts and oils give НОАК antibacterial powers. Makers mix these into НОАК во время производства. This creates packaging that stops germs and keeps products safe.

Oils like thyme or oregano act as natural preservatives. They help food last longer without chemicals. This matches the need for healthier and greener packaging. These bioactive ingredients make НОАК safer for food storage and cut down on additives.

Людям нужны экологически чистые продукты, and this trend helps businesses. Using НОАК with bioactive features shows care for the planet. Choosing this packaging supports a cleaner and healthier world.

Примечание: Bioactive НОАК works well for fresh food and ready meals. It keeps food safe and reduces waste from spoilage.

Market Growth and Trends of Polylactic Acid (НОАК)

Current Market Value and Projections

Worth $1.2 Billion in 2022

The global market for PLA packaging is growing fast. В 2022, it was worth $1.2 billion due to higher demand for green materials. Packaging is the biggest part of this market. This shows people want biodegradable options instead of regular plastics.

Expected to Hit $6.9 Billion by 2031

By 2031, the PLA market could reach $6.9 миллиард. It is expected to grow by 13.2% each year from 2023 к 2031. More industries like food, Здравоохранение, and retail are using PLA. Companies are also creating new ideas to meet eco-friendly goals, making the market exciting.

Key Reasons for Market Growth

Need for Eco-Friendly Materials

People care more about the environment now. This makes PLA popular because it breaks down naturally. Consumers want renewable materials to lower their carbon footprint. PLA is a top choice for packaging, especially in areas worried about plastic waste.

Rules About Plastic Waste

Laws are helping PLA become more common. Countries like France and India have strict rules against single-use plastics. France plans to stop using single-use plastic packaging by 2040. India banned some plastic items in 2022. These rules push industries to use PLA instead.

Main Reason | Подробности |

|---|---|

Government Rules | Laws supporting biodegradable materials help PLA grow. France and India lead with bans on single-use plastics and rewards for eco-friendly choices. |

Environmental Concerns | More people worry about plastic pollution. PLA’s renewable and biodegradable features make it a great solution to this problem. |

Regional Market Highlights

Asia Pacific Leads the Market

Asia Pacific is the top region for PLA growth. Its strong industries and growing middle class drive demand. Countries like China, Япония, and India play big roles. More packaged goods and helpful government rules also boost PLA use.

Asia Pacific is the fastest-growing PLA market.

Китай, Япония, and India are key contributors.

Middle-class growth increases demand for packaged products.

Policies encourage eco-friendly materials in the region.

Growth in Europe and North America

Europe and North America are also seeing more PLA use. In North America, the U.S. and Canada lead because they focus on sustainability. Rules support biodegradable materials, and consumers prefer green products. Европа, with countries like Germany and France, also uses PLA to cut plastic waste.

North America focuses on sustainability with strong rules.

Europe works to reduce plastic waste using PLA.

Consumer interest in eco-friendly products drives growth in both regions.

Key Players and Industry Developments

NatureWorks and Production Expansion

NatureWorks is a top company in the НОАК industry. They make Ingeo™, а НОАК brand from renewable plants. Their products are used in food packaging, 3D Печать, and hygiene items. NatureWorks has helped spread the use of НОАК worldwide.

Recently, NatureWorks has worked to grow its production. They are building a new factory in Thailand. This plant will add 75,000 metric tons of НОАК каждый год. It will use local sugarcane, making the supply chain eco-friendly. This expansion helps meet the rising demand for НОАК in Asia and other regions.

NatureWorks also focuses on improving НОАК качество. They team up with universities and labs to create better НОАК types. These new versions are useful for healthcare and electronics. NatureWorks shows how one company can lead in sustainable materials.

Вы знали? NatureWorks was the first to make НОАК on a large scale. Their work set the standard for the industry.

Competitive Landscape and Innovations

А НОАК market has many companies working on new ideas. TotalEnergies Corbion is another big name. They make strong НОАК for packaging and industrial uses. Their Luminy® НОАК is heat-resistant and durable, perfect for tough jobs.

Smaller companies also help the industry grow. Danimer Scientific, например, makes biodegradable plastics, including НОАК blends. They improve НОАК so it can compost at home. These changes make НОАК easier for people to use daily.

Teamwork is key to these advancements. Companies partner with startups, labs, and governments. BASF, for instance, works with biopolymer startups to make better materials. These partnerships create НОАК with stronger barriers and longer shelf life.

Кончик: Watch for new companies in the НОАК market. They often bring fresh ideas that change the industry.

Competition pushes companies to improve. They aim to make НОАК as good as regular plastics but eco-friendly. This benefits consumers by making НОАК products cheaper, stronger, and better for the planet.

Practical Tips for Businesses Using Polylactic Acid (НОАК)

Deciding if PLA Fits Your Brand

Balancing Green Goals with Real Challenges

Switching to PLA can help your brand go green. Many people now prefer eco-friendly products. Studies show над 90% of green-marketed items sell better than regular ones. Using PLA can make your brand more attractive. Но, you need to think about its costs and limits.

PLA makes less pollution than regular plastics, which is great. Однако, it has some downsides. Например, НОАК doesn’t handle heat well and isn’t as good at keeping out air or water as PET. These issues might make it less useful for some food packaging. Check if PLA works for your product needs before switching.

“Brands like PG Tips and Starbucks use PLA for tea bags and cups. This shows it works well in food service.”

Knowing PLA’s Weaknesses

PLA costs more to make than regular plastics. It also doesn’t do well with heat or moisture. Even though it’s pricier, it’s better for the planet and made from plants. Think about these trade-offs when deciding if PLA is right for you. Custom solutions, like mixing PLA with other materials, can help fix some of its problems.

Working with Composting and Recycling Centers

Teaming up with composting and recycling centers is key for managing PLA. Many places don’t have the right systems to handle PLA. Without proper composting, PLA often ends up in landfills where it doesn’t break down. Partnering with local composting centers ensures PLA is disposed of correctly.

A report says PLA is often treated as trash in recycling. This shows why it’s important to teach facilities about PLA. Work with composting centers to set clear rules for handling PLA. These partnerships can improve your brand’s green efforts and help create a circular economy.

“Building ties with composting centers can solve PLA disposal issues and boost its eco-friendliness.”

Teaching Customers How to Dispose of PLA

Helping customers understand how to throw away PLA is very important. Many people don’t know PLA needs special composting to break down. Clear labels and instructions can guide them. Look for certifications like BPI to show your products meet composting standards.

People are willing to pay more for green products. Use this chance to teach them about PLA’s benefits and how to dispose of it. Например, explain that composting PLA can cut emissions equal to 42 угольные электростанции.

Add disposal tips to your packaging.

Support local composting programs to help manage PLA.

Share educational posts to inform customers about PLA.

By teaching customers, you can show your brand cares about the planet and make a bigger positive impact.

Using PLA for Branding and Marketing

Showcasing Eco-Friendly Efforts

Using Polylactic Acid (НОАК) packaging shows your brand cares about the planet. Many shoppers today prefer products that match their green values. Choosing НОАК helps your business stand out as eco-friendly.

Sharing your green efforts builds trust with customers. Например, explain how НОАК lowers carbon emissions and cuts plastic waste. Use your website, social media, or product labels to share these benefits. Adding labels like the Biodegradable Products Institute (БПИ) or USDA BioPreferred logo proves your claims are real.

Кончик: Share stories about switching to НОАК. Show how your brand is helping the environment. This honesty can attract eco-friendly buyers.

You can also team up with green groups to boost your efforts. Work with composting programs or support campaigns to reduce plastic waste. These actions show your company cares about more than just making money.

Flexible Packaging Options

НОАК packaging is flexible and helps your brand stand out. Its design can be shaped to fit different products. Whether you need clear food containers or stylish retail packaging, НОАК works well.

Customizing НОАК packaging is great for branding. You can print your logo, slogan, or eco-friendly message on it. This strengthens your brand image and shows your commitment to sustainability.

Особенность | Выгода |

|---|---|

Flexible Design | Fits many product shapes and sizes. |

Easy to Print On | Great for logos and messages. |

Clear Look | Lets customers see the product, building trust. |

Примечание: Использовать НОАК’s clear design to highlight your product’s quality. This can attract buyers who value transparency.

You can also add bright colors or textures to make НОАК packaging more appealing. These features help your products stand out on shelves. By mixing style with function, you get packaging that protects your items and boosts your brand.

Contact Us

Try PLA’s flexible options today. Create packaging that shows your values and grabs attention.

Полилактановая кислота (НОАК) is a better option for reducing plastic waste. It helps the environment by cutting emissions and breaking down naturally. Но, problems like few composting centers and higher prices need fixing. Its rising use shows it can help create a greener future.

Your business can make a difference by using PLA packaging. This choice helps the planet and meets customer demand for green products. Start using PLA now to support a cleaner and healthier world.

Часто задаваемые вопросы

What is PLA, and why is it eco-friendly?

НОАК, or Polylactic Acid, is a plastic made from plants like corn or sugarcane. It’s eco-friendly because it lowers greenhouse gases, uses less energy to make, and breaks down in industrial composting.

Can PLA be composted at home?

Composting PLA at home is hard. It needs high heat and special conditions only found in industrial composting centers. Check local composting options to dispose of it correctly.

Кончик: Искать BPI-certified products to ensure they can be composted.

How is PLA different from regular plastics?

PLA is made from plants and breaks down naturally, unlike regular plastics made from oil. It creates fewer greenhouse gases when produced but needs special composting and doesn’t handle heat well.

Is PLA safe for food packaging?

Да, PLA is safe for food. А FDA approves it for food use. It’s non-toxic and keeps food fresh by blocking air. It’s often used for cups, plates, and containers.

What are the main problems with PLA?

PLA has some issues like being more expensive, needing special composting centers, and not handling heat or moisture well. These problems limit its use and benefits.

Does PLA break down in landfills?

Нет, PLA doesn’t break down well in landfills. It needs high heat and moisture from industrial composting to decompose. Without these, it can last for years.

How can businesses teach people about PLA disposal?

Businesses can add clear instructions on packaging. They can also work with composting centers and share tips online to help people dispose of PLA properly.

Примечание: Teaching people how to dispose of PLA helps it work better for the planet.

Is PLA worth the cost for businesses?

PLA costs more than regular plastics because of how it’s made. But its eco-friendly features attract customers who care about the planet, making it a smart choice for green brands.

Contact Us

Think about your brand’s goals to see if PLA fits your eco-friendly plans.