Ein umfassender Leitfaden für PLA -Verpackungen und Sustainabili

Leitfaden zur PLA -Verpackung

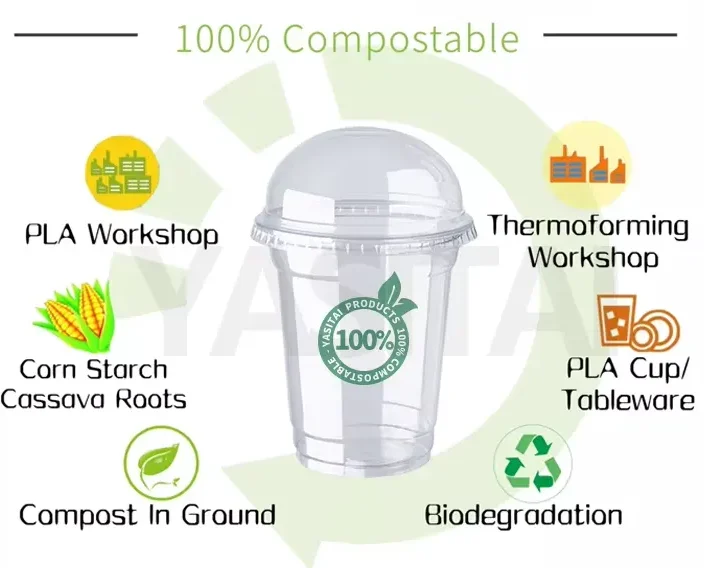

Polylactsäure (PLA) revolutioniert die Art und Weise, wie wir uns Verpackungslösungen nähern. Mit der Welt vor einem bedeutenden plastischen Problem, Erzeugen 400 Millionen Tonnen Abfall jährlich, Die Einführung von PLA Cups bietet eine nachhaltigere Alternative. Im Gegensatz zu herkömmlichen Optionen wie dem Pet Cup Und PP Cup, PLA ist biologisch abbaubar und kompostierbar, natürlich zusammenbrechen und dem Planeten zugute kommen. Abgeleitet von erneuerbaren Ressourcen wie Mais und Zuckerrohr, PLA ist im Vergleich zu konventionellen Kunststoffen umweltfreundlicher. Unternehmen wie TotalEnergies Corbion zeigen, dass PLA produziert 75% weniger Kohlenstoffverschmutzung als Kunststoffe auf Ölbasis. Da sich der PLA -Markt schnell erweitert, wachsen bei ungefähr 12% Jedes Jahr, Viele Branchen nehmen PLA an, um den Klimawandel zu bekämpfen und umweltfreundliche Anforderungen zu erfüllen, insbesondere bei der Betrachtung der Unterschiede in der Nachhaltigkeit zwischen Pp gegen pet.

Key Takeaways

Polylactsäure (PLA) ist eine grüne Option anstelle regelmäßiger Kunststoffe. Es besteht aus Pflanzen wie Mais und Zuckerrohr.

PLA kann natürlich zusammenbrechen, Daher reduziert es den Müll auf Deponien.

Die Verwendung von PLA kann die schädlichen Gasemissionen bis zu bis hin zu schneiden 63%. Dies hilft bei der Bekämpfung der globalen Erwärmung.

PLA -Verwendungszwecke machen 65% weniger Energie als die Herstellung von Kunststoffen auf Ölbasis. Dies macht es für den Planeten besser.

Unternehmen können mehr bekommen umweltfreundliche Kunden durch Verwendung von PLA. Viele Menschen mögen Produkte, die der Umwelt helfen.

PLA muss den richtigen Weg weggeworfen werden. Es funktioniert am besten, wenn es an speziellen industriellen Orten kompostiert wird.

Menschen beizubringen, wie man PLA wegwirft, kann zeigen, dass Ihre Marke sich um die Natur kümmert.

Der PLA -Markt wächst schnell. Es könnte wert sein $6.9 Milliarden von 2031 Weil mehr Menschen umweltfreundliche Materialien wollen.

Was ist Polylactsäure (PLA) Und wie wird es gemacht??

Definition und Zusammensetzung von PLA

Polylactsäure (PLA) ist ein Plastik, der auf natürliche Weise zusammenbricht. Es besteht aus Pflanzen wie Mais, Zuckerrohr, oder Maniok. Im Gegensatz zu normalen Kunststoffen aus Öl, PLA verwendet erneuerbare Materialien. Es hat lange Ketten von Milchsäure, es stark und flexibel machen. PLA ist klar, Es funktioniert also gut für die Verpackung. Es hält auch Produkte vor Feuchtigkeit und Luft sicher. Aber, Es kann nicht mit hoher Hitze umgehen, Es wird also nicht für heiße Gegenstände verwendet.

Eigentum | Beschreibung |

|---|---|

Biologische Abbaubarkeit | Bricht schnell in natürliche Materialien zusammen. |

Erneuerbare Quelle | Aus Pflanzen wie Mais gemacht, Zuckerrohr, oder Maniok. |

Festigkeit und Steifheit | Stark und langlebig für viele Anwendungen. |

Wärmewiderstand | Schmilzt leicht; Nicht gut für heiße Umgebungen. |

Klarheit und Transparenz | Klar, Ideal für Lebensmittel- und Einzelhandelspackungen. |

Barriereigenschaften | Schützt Gegenstände vor Luft und Feuchtigkeit. |

Druckbarkeit | Einfach mit guten Ergebnissen zu drucken. |

Dimensionsstabilität | Hält seine Form und Größe im Laufe der Zeit. |

Der Produktionsprozess von PLA

Fermentation von Pflanzenstärke oder Zucker

PLA beginnt mit Pflanzen wie Mais oder Zuckerrohr. Diese Pflanzen werden mit Bakterien oder Hefen fermentiert. Dieser Prozess verwandelt das Pflanzenmaterial in Milchsäure. Die Qualität der Milchsäure ist sehr wichtig. Es muss rein sein, gute PLA -Produkte herzustellen.

Umwandlung auf Milchsäure und Polyltsäure

Nächste, Die Milchsäure wird gereinigt, um etwas Unerwünschtes zu entfernen. Sauberes Milchsäure wird dann durch einen Prozess, der als Polymerisation bezeichnet wird, in PLA verwandelt. Dies verbindet die Milchsäure mit langen Ketten. Für diesen Schritt werden spezielle Werkzeuge und Bedingungen verwendet. Die PLA wird dann abgekühlt und in kleine Pellets geformt. Diese Pellets werden verwendet, um Dinge wie Verpackungen oder 3D -Druckmaterialien zu erstellen.

Schritt | Beschreibung |

|---|---|

Fermentation | Verwandelt Pflanzen mit Bakterien oder Hefe in Milchsäure in Milchsäure. |

Reinigung | Reinigt die Milchsäure, um sie rein zu machen. |

Polymerisation | Verknüpft Milchsäure in lange Ketten, um PLA zu erzeugen. |

Pelletisierung | Kühlt und formt Pla in kleine Pellets. |

Verarbeitung | Verwendet Pellets, um fertige Produkte wie Verpackung herzustellen. |

Erneuerbare Rohstoffe für PLA

Mais, Zuckerrohr, und Maniok

PLA besteht aus Pflanzen wie Mais, Zuckerrohr, und Maniok. Diese Pflanzen liefern den für die Produktion benötigten Zucker oder Stärke. Die Verwendung dieser Pflanzen macht PLA für die Umwelt besser als in Öl auf Ölbasis Kunststoffe. Übrig gebliebene Teile dieser Pflanzen können auch verwendet werden, Abfall reduzieren. Zum Beispiel, Zuckerrohr -Reste können dazu beitragen, PLA zu machen.

PLA kommt von Pflanzen wie Mais, Maniok, und Zuckerrohr.

Übrig gebliebene Pflanzenteile können verwendet werden, Abfall senken.

Das Herstellen von PLA schafft weniger Umweltverschmutzung als regelmäßige Kunststoffe.

Lebenszyklusbewertungen (Lce) Überprüfen Sie, wie PLA die Umwelt beeinflusst. Sie stellen sicher, dass der Prozess schädliche Chemikalien oder zu viel Umweltverschmutzung vermeidet.

Aufkommende nicht-landwirtschaftliche Ausgangsmaterialien

Neue Möglichkeiten, um PLA -Nutzung anderer Dinge als Pflanzen zu verwenden. Dazu gehören Algen, Lebensmittelabfälle, und sogar Kohlendioxid. Die Verwendung dieser Materialien bedeutet, dass weniger Ackerland und Wasser benötigt werden. Zum Beispiel, PLA auf Algenbasis kann in Gebieten wachsen, in denen Pflanzen nicht können, Hilfe bei der Rettung von Ackerland für Lebensmittel.

Vergleich mit Kunststoffen auf Erdölbasis

PLA gegen PET und PP

Polylactsäure (PLA) unterscheidet sich von Kunststoffen wie HAUSTIER Und PP. PLA wird aus Pflanzen hergestellt, während HAUSTIER Und PP Komm aus Öl. Das macht PLA eine grünere Option. Im Gegensatz zu HAUSTIER, das kann recycelt werden, PLA ist kompostierbar. Es bricht unter bestimmten Bedingungen in natürliche Materialien zusammen, Reduzierung von Deponieabfällen.

Herstellung PLA Nutzt weniger Energie als die Herstellung von Kunststoffen auf Ölbasis. Studien zeigen PLA Bedürfnisse 65% weniger Energie produzieren. Es schafft auch 63% Weniger Treibhausgase. Diese Tatsachen zeigen, wie PLA hilft dem Planeten mehr als HAUSTIER Und PP. Aber PLA hat Grenzen. Es kann nicht mit hoher Hitze umgehen, Es ist also nicht gut für einige Verwendungen, die wo HAUSTIER oder PP arbeiten besser.

Umwelt- und wirtschaftliche Vorteile

Wechseln auf PLA hilft der Umwelt in vielerlei Hinsicht. Seine Produktion veröffentlicht weniger Treibhausgase, Kampf gegen den Klimawandel. PLA stützt sich auch nicht auf begrenzte Ölressourcen. Es verwendet schnell wachsende Pflanzen wie Mais oder Zuckerrohr, Ölverbrauch schneiden. Gruppen mögen die EPA Und FDA Unterstützung biologisch abbaubarer Kunststoffe wie PLA. Dies zeigt, dass umweltfreundliche Materialien wächst.

Verwendung PLA macht auch Sinn für Unternehmen. Mehr Menschen kümmern sich darum, dem Planeten zu helfen. Unternehmen verwenden PLA kann diese Kunden anziehen und strengere Regeln für Plastikmüll befolgen. Während PLA kostet mehr zu machen als HAUSTIER oder PP, Seine Vorteile sind es wert. Wählen PLA Unterstützt eine kreisförmige Wirtschaft und zeigt, dass Ihre Marke sich um Nachhaltigkeit kümmert.

Tipp: Lehren Sie Kunden, wie man kompostiert PLA. Die richtige Entsorgung stellt sicher, dass es der Umwelt hilft.

Umweltvorteile von Polylactsäure (PLA)

Weniger Treibhausgasemissionen

Unter Verwendung von Polyltsäure (PLA) Hilft bei der Senkung der Treibhausgasemissionen bei. Im Gegensatz zu Kunststoffen auf Ölbasis, PLA besteht aus Pflanzen wie Mais. Diese Pflanzen nehmen Kohlendioxid auf, während sie wachsen, einige Emissionen ausbalancieren. Studien zeigen 63%. Dies hilft beim Bekämpfung des Klimawandels und reduziert die CO2 -Fußabdrücke weltweit.

Lebenszyklusbewertungen (Lce) Überprüfen Sie, wie sich die PLA auf die Umwelt auswirkt. Sie vergleichen die Emissionen von PLA mit regelmäßigen Kunststoffen. Die Ergebnisse zeigen, dass PLA einen kleineren CO2 -Fußabdruck hat. Die Kompostierung von PLA hält auch Abfall von Mülldeponien fern, Methangase schneiden. Methan ist schädlich für den Planeten, Es ist also sehr wichtig, es zu reduzieren.

Evidenztyp | Beschreibung |

|---|---|

Lebenszyklusbewertungen (LCA) | LCAs zeigen, wie besser PLA für den Planeten besser ist als reguläre Kunststoffe. |

Kompostabilität | Kompostierung pla schneidet Treibhausgase gleich 42 Kohlekraftwerke. |

BPI -Zertifizierung | Beweist, dass PLA Kompostierungsregeln erfüllt und ordnungsgemäß zusammenbricht. |

Verbraucht weniger Energie, um sie zu machen

Die Herstellung von PLA verbraucht weniger Energie als Kunststoffe auf Ölbasis zu machen. Der Prozess verwendet Pflanzenzucker, brauchen 65% weniger Energie als normale Kunststoffe. Dies spart Energie und senkt die Umweltauswirkungen von PLA. Die Auswahl von PLA sparen Energie und reduziert die Notwendigkeit von Öl.

Energie sparen hilft Unternehmen auch, Geld zu sparen. Während PLA im Voraus mehr kostet, Die Energieeinsparungen können die Kosten ausgleichen. Dies macht PLA zu einer intelligenten Wahl für umweltfreundliche Unternehmen.

Bricht natürlich zusammen

Die beste Funktion von PLA ist, dass es auf natürliche Weise zusammenbricht. Regelmäßige Kunststoffe dauern Hunderte von Jahren, Aber Pla wird in Wasser, Kohlendioxid, und organisches Material. Dies hilft, Plastikabfälle in der Umwelt zu reduzieren.

Industriekompostierungsregeln

PLA erfüllt strenge Kompostierungsregeln, Wie solche aus dem Institut für biologisch abbaubare Produkte (BPI). Diese Regeln stellen sicher, dass PLA in Industriekompostationszentren zusammenbricht. Diese Zentren verwenden hohe Hitze und Feuchtigkeit, um PLA zu zersetzen,. Suchen Sie nach BPI -Etiketten, um zu wissen, ob ein PLA -Produkt kompostierbar ist.

Herausforderungen für die Kompostierung von Heimkompostieren

PLA arbeitet besser im industriellen Kompostieren als zu Hause. Home Composting hat nicht die richtigen Bedingungen für PLA, um vollständig zusammenzubrechen. Aber neue Ideen verbessern die PLA für die Kompostierung zu Hause. Um die meisten Vorteile zu erzielen, Entsorgung von PLA in industriellen Kompostierungszentren.

Beitrag zur kreisförmigen Wirtschaftlichkeit

Sich von fossilen Brennstoffen wegziehen

PLA Hilft bei der Verringerung der Verwendung fossiler Brennstoffe. Regelmäßige Kunststoffe werden aus Öl hergestellt, das ist begrenzt und verschmutzt. PLA kommt von Pflanzen wie Mais und Zuckerrohr, die zurückwachsen. Verwendung PLA senkt die Ölnachfrage und unterstützt eine grünere Zukunft.

Herstellung PLA passt zu der Idee, Materialien wiederzuverwenden. Kunststoffe auf Ölbasis werden oft als Müll in Deponien. Aber PLA kann kompostiert oder recycelt werden, wenn sie richtig gemacht werden. Dies reduziert Abfall und hält die Materialien im Einsatz. Wählen PLA zeigt, dass Sie sich um den Planeten kümmern und weniger Ölverbrauch wünschen.

Tipp: Auswahl von Gegenständen, die gekennzeichnet sind “Biobasiert” oder “kompostierbar” Um die Kunststoff auf Ölbasis zu reduzieren.

Plastikverschmutzung stoppen

Plastikmüll schadet jedes Jahr Ozeane und Natur. PLA hilft, weil es unter Kompostierungsbedingungen natürlich zusammenbricht. Im Gegensatz zu normalen Kunststoffen, die jahrhundertelungen dauern, PLA verwandelt sich in Wasser, Kohlendioxid, und natürliches Material. Dies senkt den langfristigen Schaden für die Umwelt.

Sie können die Plastikverschmutzung stoppen, indem Sie wegwerfen PLA der richtige Weg. Kompostierungszentren sind die besten Orte für PLA zusammenbrechen. Lehren Sie den Menschen über diese Optionen, um zu helfen. Bei richtiger Handhabung, PLA Hält Müll aus Ozeanen und schützt Tiere.

Notiz: PLA braucht besondere Bedingungen, um zusammenzubrechen. Unterstützen PLA.

Herausforderungen und Einschränkungen der Polyltsäure (PLA)

Entsorgung und Kompostierungsinfrastruktur

Eingeschränkter Zugang zu Industriekompostierungsanlagen

Polylinsäure loswerden (PLA) kann hart sein. Viele Gebiete haben keine Kompostierungszentren für PLA. Diese Zentren verwenden eine hohe Hitze, um zusammenzubrechen PLA richtig. Ohne sie, PLA endet oft auf Deponien. Auf Deponien, Es zersetzt sich nicht so wie es sollte. Dies verwirrt Menschen, die denken PLA ist immer kompostierbar. An vielen Orten fehlen immer noch die richtigen Systeme für PLA Entsorgung. Dies begrenzt seine positiven Auswirkungen auf die Umwelt.

Tipp: Suchen Sie vor dem Kauf nach lokalen Kompostierungszentren PLA Produkte.

Methanemissionen auf Deponien

Werfen PLA In Deponien können Methangas verursachen. Methan ist ein starkes Gas, das den Klimawandel verschlechtert. Deponien haben nicht die richtigen Bedingungen für PLA sicher zusammenbrechen. Stattdessen, PLA kann Methan freisetzen, wenn es ohne Luft fließt. Dies schadet seinem umweltfreundlichen Bild. Es sind bessere Abfallsysteme erforderlich, um dieses Problem zu beheben.

Kosten- und Leistungsbeschränkungen

Höhere Produktionskosten im Vergleich zu herkömmlichen Kunststoffen

Herstellung PLA kostet mehr als regelmäßige Kunststoffe wie wie HAUSTIER oder PP. Dies liegt daran, dass biologische Materialien wie Mais und Zuckerrohr teurer sind. Der Prozess zu machen PLA Nutzt auch mehr Energie und befolgt strenge Regeln. Diese Faktoren machen PLA Weniger erschwinglich. Billigere Kunststoffe auf Ölbasis dominieren den Markt aus diesem Grund.

PLA Verwendet kostspielige Materialien auf pflanzlicher Basis anstelle von Öl.

Seine Produktion braucht mehr Energie und folgt strenge Regeln.

Hohe Kosten machen es weniger wettbewerbsfähig auf dem Markt.

Empfindlichkeit gegenüber Feuchtigkeit und Temperatur

PLA hat Grenzen, die sich auf die Verwendung auswirken. Es geht nicht gut mit Wärme um, so kann es schmelzen oder verzerrt. Zum Beispiel, Heiße Flüssigkeiten können ruinieren PLA Verpackung. Es blockiert auch keine Luft oder Feuchtigkeit wie HAUSTIER. Dies macht es weniger nützlich, um Essen frisch zu halten.

PLA schmilzt in hoher Hitze, seine Verwendung einschränken.

Es blockiert nicht so gut Luft oder Wasser wie HAUSTIER.

Diese Probleme machen es für einige Branchen weniger nützlich.

Ethische und ökologische Bedenken

Auswirkungen der Nutzung landwirtschaftlicher Pflanzen auf die Nahrungsressourcen

Herstellung PLA hängt von Pflanzen wie Mais und Zuckerrohr ab. Dies wirft Bedenken hinsichtlich der Verwendung von Nahrungsmitteln für Plastik an, anstatt Menschen zu füttern. In Gebieten mit Lebensmittelknappheit, Dies kann Probleme verschlimmern. Mit Pflanzen für PLA konkurriert auch mit Ackerland um den Anbau von Lebensmitteln. Dies kann Lebensmittelpreise erhöhen und Gemeinden schädigen.

Land- und Wasserverbrauch bei der Ernteanbau

Wachstum von Pflanzen für PLA hat Umweltabgriffen. Große Farmen können Entwaldungen verursachen und wild lebende Tiere schädigen. Sie verschmutzen auch Wasser und reduzieren die biologische Vielfalt. Berichte zeigen, dass diese landwirtschaftlichen Praktiken Ökosysteme und nahe gelegene Gemeinden beeinträchtigen können. Während PLA ist besser als Kunststoffe auf Ölbasis, Seine landwirtschaftlichen Bedürfnisse machen Bedenken hinsichtlich Nachhaltigkeit auf.

Notiz: Verwenden neuer Ideen wie Algenbasis PLA Kann die Auswirkungen der Landwirtschaft senken.

Regulierungs- und Standardisierungsprobleme

Keine klaren Bundesregeln für Kompostierbarkeit

Viele denken alle kompostierbaren Gegenstände, wie pla, leicht zusammenbrechen. Aber ohne klare Bundesregeln, Das ist nicht immer wahr. Kompostierbare Kunststoffe benötigen besondere Bedingungen, wie hohe Hitze und Feuchtigkeit, sich zersetzen. Diese Bedingungen finden sich nur in industriellen Kompostierungszentren. Leider, Nicht alle Elemente mit der Bezeichnung “kompostierbar” diese Bedürfnisse erfüllen. Dies verwirrt die Menschen und erschwert die Abfallwirtschaft.

Das USDA arbeitet an neuen Regeln für kompostierbare Biokaststoff. Diese Regeln könnten sicherstellen, dass PLA -Produkte strenge Kompostierungsstandards entsprechen. Einige Staaten haben bereits Gesetze zur besseren Kennzeichnung für kompostierbare Gegenstände. Aber ohne landesweite Regeln, Es gibt immer noch Unterschiede.

“Freiwillige Standards funktionieren nicht… Bundesregeln für Kompostierbarkeit sind erforderlich, um Konflikte zu vermeiden.”

Länder wie Frankreich sind führend, indem sie Einwegkunststoffe verbieten. Sie wollen aufhören, alle Einweg-Plastikverpackungen durchzusetzen 2040. Dies drängt die Branchen, umweltfreundliche Materialien wie PLA zu verwenden. Ähnliche USA. Richtlinien könnten den PLA -Markt erhöhen und Plastikmüll schneiden.

Land | Regulierungsdetails | Auswirkungen auf den PLA -Markt |

|---|---|---|

Frankreich | Verboten einige Einwegkunststoffe in 2021; Pläne, alle einwendigen Plastikverpackungen nach zu beenden 2040. | Ermutigt die Branchen, Biokallplastik wie PLA zu nutzen, um umweltfreundliche Ziele zu erreichen. |

Indien | Setzen Sie Regeln in 2021 Um bestimmte Einwegkunststoffe bis Juli zu verbieten 2022; Erforderliche EPR für Plastikabfälle. | Drängt die Branchen, um zu nachhaltigen Optionen wie PLA zu wechseln, um die Regeln zu befolgen. |

Bedeutung der erweiterten Produzentenverantwortung (EPR) Gesetze

EPR -Gesetze machen Unternehmen für den gesamten Lebenszyklus ihrer Produkte verantwortlich. Dazu gehört, wie sie entsorgt werden. Diese Gesetze drängen Unternehmen, eine bessere Verpackung zu erstellen und in Kompostier- oder Recyclingsysteme zu investieren. Für pla, EPR -Gesetze könnten dazu beitragen, eine ordnungsgemäße Entsorgung zu gewährleisten und die Belastung der Verbraucher zu erleichtern.

Indien hat bereits EPR -Regeln für die Verwaltung von Plastikmüll. Diese Regeln ermutigen Branchen, Alternativen wie PLA zu verwenden. In den USA, Einige Staaten verabschieden auch EPR -Gesetze, die sich auf die Auswahl der Verpackung auswirken. Bundesbehörden könnten bald Richtlinien veröffentlichen, die die Zukunft von PLA beeinflussen könnten.

Das USDA arbeitet an Regeln für kompostierbare Biokaststoff.

Einige Staaten verabschieden EPR -Gesetze, die sich auf die Verpackung auswirken.

Die Bundesrichtlinien könnten sich bald auf den PLA -Markt auswirken.

EPR -Gesetze können dazu beitragen, ein System zu schaffen, in dem Materialien wie PLA wiederverwendet oder kompostiert werden. Dies reduziert Deponieabfälle und inspiriert neue Ideen für umweltfreundliche Verpackungen. Die Unterstützung dieser Gesetze hilft dabei, einen Reiniger aufzubauen, grünere Zukunft für alle.

Anwendungen von Polyltsäure (PLA) in der Verpackung

Lebensmittelverpackung

FDA für Lebensmittelkontakt zugelassen

Polylactsäure (PLA) ist sicher für Lebensmittelverpackungen. Der FDA Genehmigt es für Lebensmittelkontakt, Sicherheit gewährleisten. Das heisst PLA kann Lebensmittel ohne Schaden aufbewahren und transportieren. Es ist ungiftig, Also schützt es Lebensmittel, während es sicher ist.

Attribut | Beweis |

|---|---|

FDA -Genehmigung | PLA wird von der genehmigt FDA für Lebensmittelverpackungen. |

Sicherheit | PLA ist sicher für Lebensmittelkontakt und Lagerung. |

Temperaturwiderstand | Verarbeitet die Hitze bis zu 110 ° C., Gut für heißes Essen. |

Barriereigenschaften | Hält Nahrung frisch mit starken Sauerstoffbarriereneigenschaften. |

Anwendungen | Für Tassen verwendet, Teller, Schalen, und Besteck. |

Popularität | Häufig für frische Produkte, Mahlzeiten, und Getränke. |

Antibakterielle Eigenschaften | Zusätzte Agenten verbessern die Lebensmittelsicherheit und die Haltbarkeitsdauer. |

Vielseitig und formell für verschiedene Bedürfnisse

PLA ist flexibel und funktioniert für viele Verpackungsbedürfnisse. Es wird für Tassen verwendet, Teller, Schalen, und sogar Besteck. Seine Form kann so eingestellt werden, dass sie unterschiedliche Verwendungszwecke anpassen. PLA Hält Lebensmittel auch frisch, indem es Sauerstoff blockiert. Es ist großartig für frische Produkte, Mahlzeiten, und Getränke. Das macht PLA ein praktisches und Umweltfreundliche Wahl.

PLA ist sicher für Lebensmittelkontakt, genehmigt durch die FDA.

Es behandelt Wärme bis zu 110 ° C., Gut für heiße Lebensmittel.

Zu den gemeinsamen Verwendungen gehören Tassen, Teller, und Klamshellbehälter.

Es hält Nahrung frisch mit starken Sauerstoffbarrieren.

Gesundheits- und pharmazeutische Verwendungszwecke

Antimikrobielle Additive zur Verhinderung der Kontamination

Im Gesundheitswesen, PLA kann die Kontamination mit besonderen Zusatzstoffen stoppen. Diese Additive blockieren Keime, Herstellung PLA Ideal für medizinische Werkzeuge. Es wird in chirurgischen Werkzeugen und Einweg -Gesundheitsgegenständen verwendet. Seine Keimkampfeigenschaften tragen dazu bei, die Infektionsrisiken zu senken.

Bewerbungsbereich | Antimikrobielle Eigenschaften | Zusätzliche Notizen |

|---|---|---|

Gesundheitswesen und pharmazeutische | PLA Kann Additive umfassen, um das Keimwachstum zu stoppen. | Wird in medizinischen Instrumenten und Einweg -Gesundheitsgegenständen verwendet. |

Bioaktive Zutaten | Natürliche Mittel wie Pflanzenextrakte können hinzugefügt werden. | Erfüllt die Nachfrage nach umweltfreundlichen Gesundheitslösungen. |

Innovationen | Neue Beschichtungen verbessern sich PLAKeimblockierungsfähigkeit. | Macht PLA Besser zur Reduzierung von Kontaminationsrisiken. |

Anwendungen in medizinischen Geräten

PLA Funktioniert gut für medizinische Werkzeuge, da es für den Körper sicher ist. Es wird in Stichen verwendet, Drogenabgabesysteme, und Einwegwerkzeuge. Natürliche Zutaten wie Pflanzenöle können hinzugefügt werden, um es umweltfreundlich zu machen. Neue Beschichtungen machen auch PLA Besser Keime stoppen.

Konsumgüter und Einzelhandel

Biologisch abbaubare Optionen für alltägliche Produkte

PLA bricht natürlich zusammen, es machen Ideal für tägliche Gegenstände. Es wird in Einkaufstaschen verwendet, Utensilien, und Verpackung. Seine Fähigkeit, sich zu zersetzen, appelliert an ökobewusste Käufer. Wählen PLA Hilft bei der Reduzierung von Plastikmüll und unterstützt Nachhaltigkeit.

Anpassbare Lösungen für das Branding

PLA Die Verpackung kann für Unternehmen angepasst werden. Das klare Design ermöglicht es Kunden, das Produkt im Inneren zu sehen. Sie können darauf drucken, Es ist großartig für das Branding. Diese Mischung aus Stil und Funktion macht PLA Beliebt für Einzelhandelsverpackungen.

Tipp: Verwenden PLA Verpackung, um Ihre umweltfreundlichen Bemühungen zu zeigen und umweltfreundliche Kunden anzulocken.

Innovationen in der PLA -Verpackung

Verbesserte Barriereigenschaften

Neue Verbesserungen machen PLA Verpackung besser beim Schutz von Gegenständen. Alt PLA hatte Probleme, Luft und Wasser zu blockieren. Jetzt, Wissenschaftler verwenden Nanokompositen und geschichtete Filme Um dies zu beheben. Diese Veränderungen helfen, Lebensmittel länger frisch zu halten. Zum Beispiel, Snacks bleiben lecker und sicher mit diesen Materialien.

Nanokompositen fügen winzige Partikel hinzu, um zu stärken PLA. Diese Partikel verhindern, dass Luft und Wasser durchkommen. Geschichtete Filme mischen verschiedene Materialien, um sie zu machen PLA härter. Beide Methoden verbessern sich PLA Für Essen und Trinken Verpackung. Diese Upgrades machen PLA so gut wie normale Kunststoffe, aber umweltfreundlich.

Tipp: Wählen PLA Verpackung mit besseren Barrierefunktionen. Es eignet sich hervorragend für Essen und sensible Gegenstände.

Integration bioaktiver Zutaten

Hinzufügen natürliche Zutaten ist eine weitere coole Veränderung für PLA. Pflanzenextrakte und Öle geben PLA antibakterielle Kräfte. Macher mischen diese in PLA während der Produktion. Dies schafft Verpackungen, die Keime stoppt und die Produkte sicher hält.

Öle wie Thymian oder Oregano fungieren als natürliche Konservierungsstoffe. Sie helfen, Lebensmittel ohne Chemikalien länger zu halten. Dies entspricht der Notwendigkeit gesünderer und umweltfreundlicherer Verpackungen. Diese bioaktiven Zutaten machen PLA sicherer für die Lagerung von Lebensmitteln und die Zusatzstoffe reduziert.

Die Leute wollen umweltfreundliche Produkte, Und dieser Trend hilft Unternehmen. Verwendung PLA Mit bioaktiven Funktionen zeigt die Pflege des Planeten. Die Auswahl dieser Verpackung unterstützt eine sauberere und gesündere Welt.

Notiz: Bioaktiv PLA Funktioniert gut für frisches Essen und vorbereitende Mahlzeiten. Es hält Lebensmittel sicher und reduziert den Verderb von Verschwendung.

Marktwachstum und Trends der Polylactsäure (PLA)

Aktueller Marktwert und Projektionen

Wert $1.2 Milliarden in 2022

Der globale Markt für PLA -Verpackungen wächst schnell. In 2022, Es war wert $1.2 Milliarden aufgrund einer höheren Nachfrage nach grünen Materialien. Die Verpackung ist der größte Teil dieses Marktes. Dies zeigt, dass Menschen biologisch abbaubare Optionen anstelle regelmäßiger Kunststoffe wünschen.

Erwartet zu schlagen $6.9 Milliarden von 2031

Von 2031, Der PLA -Markt könnte erreichen $6.9 Milliarde. Es wird erwartet, dass es durch wachsen 13.2% Jedes Jahr von 2023 Zu 2031. Mehr Branchen wie Lebensmittel, Gesundheitspflege, und Einzelhandel nutzen PLA. Unternehmen schaffen auch neue Ideen, um umweltfreundliche Ziele zu erreichen, den Markt spannend machen.

Hauptgründe für das Marktwachstum

Bedarf für umweltfreundliche Materialien

Menschen interessieren sich jetzt mehr um die Umwelt. Dies macht PLA beliebt, weil es natürlich zusammenbricht. Verbraucher möchten, dass erneuerbare Materialien ihren CO2 -Fußabdruck senken. PLA ist eine oberste Wahl für Verpackungen, Besonders in Gebieten, die sich um Plastikabfälle besorgt haben.

Regeln über Plastikabfälle

Gesetze helfen dabei, häufiger zu werden. Länder wie Frankreich und Indien haben strenge Regeln gegen Einzelstoffe mit Einzelnutzung. Frankreich plant, die Einweg-Plastikverpackung von Einwegszusammenhänge abzusetzen 2040. Indien hat einige Plastikartikel verboten 2022. Diese Regeln drängen die Branchen, stattdessen PLA zu verwenden.

Hauptgrund | Details |

|---|---|

Regierungsregeln | Gesetze, die biologisch abbaubare Materialien unterstützen. Frankreich und Indien führen mit Verboten für Einwegkunststoffe und Belohnungen für umweltfreundliche Entscheidungen. |

Umweltprobleme | Weitere Menschen machen sich Sorgen um Plastikverschmutzung. Die erneuerbaren und biologisch abbaubaren Funktionen von PLA machen es zu einer großartigen Lösung für dieses Problem. |

Regionale Markthighlights

Der asiatisch -pazifische Raum führt den Markt

Der asiatisch -pazifische Raum ist die Top -Region für das PLA -Wachstum. Seine starken Branchen und die wachsende Mittelklasse treiben die Nachfrage vor. Länder wie China, Japan, und Indien spielen große Rollen. Weitere verpackte Waren und hilfreiche Regeln der Regierung steigern auch die PLA -Verwendung.

Der asiatisch-pazifische Raum ist der am schnellsten wachsende PLA-Markt.

China, Japan, und Indien sind wichtige Mitwirkende.

Das Wachstum der Mittelklasse erhöht die Nachfrage nach verpackten Produkten.

Richtlinien fördern umweltfreundliche Materialien in der Region.

Wachstum in Europa und Nordamerika

Europa und Nordamerika sehen auch mehr PLA -Nutzung. In Nordamerika, die USA. und Kanada führen, weil sie sich auf Nachhaltigkeit konzentrieren. Regeln unterstützen biologisch abbaubare Materialien, und Verbraucher bevorzugen grüne Produkte. Europa, mit Ländern wie Deutschland und Frankreich, Verwendet auch PLA, um Kunststoffabfälle zu schneiden.

Nordamerika konzentriert sich auf Nachhaltigkeit mit starken Regeln.

Europa setzt Plastikabfälle mit PLA zusammen.

Verbraucherinteresse an umweltfreundlichen Produkten fördert das Wachstum in beiden Regionen.

Schlüsselakteure und Branchenentwicklungen

Naturworks und Produktionserweiterung

Natureworks ist ein Top -Unternehmen in der PLA Industrie. Sie machen Ingeo ™, A PLA Marke aus erneuerbaren Pflanzen. Ihre Produkte werden in Lebensmittelverpackungen verwendet, 3D Druck, und Hygieneartikel. Natureworks hat dazu beigetragen, die Verwendung von zu verbreiten PLA weltweit.

Kürzlich, Natureworks hat daran gearbeitet, seine Produktion auszubauen. Sie bauen eine neue Fabrik in Thailand. Diese Pflanze wird hinzufügen 75,000 metrische Tonnen von PLA Jedes Jahr. Es wird lokales Zuckerrohr verwenden, Machen Sie die Lieferkette umweltfreundlich. Diese Expansion hilft bei der steigenden Nachfrage nach PLA in Asien und anderen Regionen.

Naturworks konzentriert sich auch auf die Verbesserung PLA Qualität. Sie verbinden sich mit Universitäten und Labors, um besser zu schaffen PLA Typen. Diese neuen Versionen sind nützlich für Gesundheitswesen und Elektronik. Natureworks zeigt, wie ein Unternehmen in nachhaltigen Materialien führen kann.

Wussten Sie? Natureworks war die erste, die machte PLA in großem Maßstab. Ihre Arbeit legte den Standard für die Branche.

Wettbewerbslandschaft und Innovationen

Der PLA In Market arbeiten viele Unternehmen an neuen Ideen. TotalEnergies Corbion ist ein weiterer großer Name. Sie machen stark PLA Für Verpackungen und industrielle Verwendungen. Ihr Luminy® PLA ist hitzebeständig und langlebig, Perfekt für harte Jobs.

Kleinere Unternehmen helfen auch der Branche, zu wachsen. Danimer Scientific, Zum Beispiel, macht biologisch abbaubare Kunststoffe, einschließlich PLA Mischungen. Sie verbessern sich PLA So kann es zu Hause kompostieren. Diese Änderungen machen PLA Leichter für Menschen, täglich zu benutzen.

Teamwork ist der Schlüssel zu diesen Fortschritten. Unternehmen arbeiten mit Startups zusammen, Labors, und Regierungen. Basf, zum Beispiel, Arbeitet mit Biopolymer -Startups, um bessere Materialien zu machen. Diese Partnerschaften erstellen PLA mit stärkeren Barrieren und längerer Haltbarkeit.

Tipp: Achten Sie auf neue Unternehmen in der PLA Markt. Sie bringen oft neue Ideen mit, die die Branche verändern.

Wettbewerb drängt Unternehmen, sich zu verbessern. Sie wollen machen PLA so gut wie normale Kunststoffe, aber umweltfreundlich. Dies kommt den Verbrauchern zugute, indem sie machen PLA Produkte billiger, stärker, und besser für den Planeten.

Praktische Tipps für Unternehmen, die Polylactsäure verwenden (PLA)

Entscheidung, ob PLA zu Ihrer Marke passt

Grünes Ziele mit echten Herausforderungen ausgleichen

Wenn Sie zu PLA wechseln, können Sie Ihrer Marke grün werden. Viele Menschen bevorzugen jetzt umweltfreundliche Produkte. Studien zeigen über 90% von grün marktierten Artikeln verkaufen sich besser als normale. Die Verwendung von PLA kann Ihre Marke attraktiver machen. Aber, Sie müssen über seine Kosten und Grenzen nachdenken.

PLA macht weniger Umweltverschmutzung als regelmäßige Kunststoffe, Welches ist großartig. Jedoch, Es hat einige Nachteile. Zum Beispiel, PLA Umgang nicht gut mit Wärme und ist nicht so gut darin, Luft oder Wasser auszuhalten wie Haustier. Diese Probleme können es für einige Lebensmittelverpackungen weniger nützlich machen. Überprüfen Sie, ob PLA vor dem Wechseln für Ihre Produktanforderungen funktioniert.

“Marken mögen PG -Tipps und Starbucks Verwenden Sie PLA für Teebeutel und Tassen. Dies zeigt, dass es im Food -Service gut funktioniert.”

Plas Schwächen kennen

PLA kostet mehr zu machen als normale Kunststoffe. Es läuft auch nicht gut mit Hitze oder Feuchtigkeit. Obwohl es teurer ist, Es ist besser für den Planeten und besteht aus Pflanzen. Denken Sie an diese Kompromisse bei der Entscheidung, ob PLA für Sie geeignet ist. Benutzerdefinierte Lösungen, wie das Mischen von PLA mit anderen Materialien, kann dazu beitragen, einige seiner Probleme zu beheben.

Arbeiten mit Kompostierungs- und Recyclingzentren

Die Zusammenarbeit mit Kompostierung und Recyclingzentren ist der Schlüssel zum Verwalten von PLA. Viele Orte haben nicht die richtigen Systeme, um PLA zu bewältigen. Ohne richtige Kompostierung, PLA endet oft auf Deponien, auf denen es nicht zusammenbricht. Die Partnerschaft mit lokalen Kompostierungszentren stellt sicher, dass die PLA korrekt entsorgt wird.

In einem Bericht heißt es, dass PLA häufig als Müll im Recycling behandelt wird. Dies zeigt, warum es wichtig ist, Einrichtungen über PLA zu unterrichten. Arbeiten Sie mit Kompostierungszentren zusammen, um klare Regeln für den Umgang mit PLA festzulegen. Diese Partnerschaften können die umweltfreundlichen Bemühungen Ihrer Marke verbessern und dazu beitragen, eine kreisförmige Wirtschaftlichkeit zu schaffen.

“Das Aufbau von Beziehungen zu Kompostierungszentren kann PLA-Entsorgungsprobleme lösen und ihre Umweltfreundlichkeit steigern.”

Kunden beibringen, wie sie PLA entsorgen können

Kunden zu helfen zu verstehen, wie man PLA wegwirft, ist sehr wichtig. Viele Menschen wissen nicht, dass PLA besondere Kompostierung benötigt, um zusammenzubrechen. Klare Etiketten und Anweisungen können sie leiten. Suchen Sie nach Zertifizierungen wie BPI, um Ihre Produkte zu zeigen, die Kompostierungsstandards erfüllen.

Die Menschen sind bereit, mehr für grüne Produkte zu bezahlen. Nutzen Sie diese Chance, um ihnen die Vorteile von PLA zu unterrichten und wie Sie es entsorgen können. Zum Beispiel, Erklären Sie, dass die Kompostierung von PLA Emissionen gleich reduzieren kann 42 Kohlekraftwerke.

Fügen Sie Ihrer Verpackung Entsorgungstipps hinzu.

Unterstützen Sie lokale Kompostierungsprogramme, um die PLA zu verwalten.

Teilen Sie Bildungsbeiträge, um Kunden über PLA zu informieren.

Durch Unterrichten von Kunden, Sie können Ihre Marke zeigen, die sich um den Planeten kümmern und einen größeren positiven Einfluss haben.

Verwendung von PLA für Branding und Marketing

Umweltfreundliche Anstrengungen vorstellen

Unter Verwendung von Polyltsäure (PLA) Verpackung zeigt, dass Ihre Marke sich um den Planeten kümmert. Viele Käufer bevorzugen heute Produkte, die ihren grünen Werten entsprechen. Wählen PLA Hilft Ihrem Unternehmen, sich als umweltfreundlich auszusprechen.

Wenn Sie Ihre grünen Bemühungen teilen, werden Vertrauen mit Kunden aufgebaut. Zum Beispiel, Erklären Sie, wie PLA senkt die Kohlenstoffemissionen und schneidet Kunststoffabfälle. Verwenden Sie Ihre Website, Social Media, oder Produktetiketten, um diese Vorteile zu teilen. Hinzufügen von Etiketten wie dem biologisch abbaubaren Produkten Institut (BPI) oder USDA -Bio -Logo beweist, dass Ihre Ansprüche real sind.

Tipp: Teilen Sie Geschichten über den Umschalten auf PLA. Zeigen Sie, wie Ihre Marke der Umwelt hilft. Diese Ehrlichkeit kann umweltfreundliche Käufer anziehen.

Sie können sich auch mit grünen Gruppen zusammenschließen, um Ihre Bemühungen zu steigern. Arbeiten Sie mit Kompostierungsprogrammen oder Unterstützung von Kampagnen zur Reduzierung von Plastikmüll. Diese Aktionen zeigen, dass Ihr Unternehmen sich um mehr als nur Geld kümmert.

Flexible Verpackungsoptionen

PLA Die Verpackung ist flexibel und hilft Ihrer Marke, hervorzuheben. Sein Design kann so geformt werden, dass sie verschiedene Produkte anpassen. Egal, ob Sie klare Lebensmittelbehälter oder stilvolle Einzelhandelsverpackungen benötigen, PLA funktioniert gut.

Anpassung PLA Verpackung eignet sich hervorragend zum Branding. Sie können Ihr Logo drucken, Slogan, oder umweltfreundliche Nachricht darauf. Dies stärkt Ihr Markenimage und zeigt Ihr Engagement für Nachhaltigkeit.

Besonderheit | Nutzen |

|---|---|

Flexible Design | Passt viele Produktformen und Größen. |

Leicht zu drucken | Ideal für Logos und Nachrichten. |

Klarer Blick | Lassen Sie die Kunden das Produkt sehen, Vertrauen aufbauen. |

Notiz: Verwenden PLADas klare Design, um die Qualität Ihres Produkts hervorzuheben. Dies kann Käufer anziehen, die Transparenz schätzen.

Sie können auch leuchtende Farben oder Texturen hinzufügen, die Sie machen können PLA Verpackung ansprechender. Diese Funktionen helfen Ihren Produkten, sich in den Regalen abzuheben. Durch Mischen von Stil mit Funktion, Sie erhalten Verpackungen, die Ihre Artikel schützen und Ihre Marke stärken.

Kontaktieren Sie uns

Probieren Sie noch heute die flexiblen Optionen von PLA aus. Erstellen Sie Verpackungen, die Ihre Werte anzeigen und Aufmerksamkeit erregen.

Polylactsäure (PLA) ist eine bessere Option zur Reduzierung von Plastikmüll. Es hilft der Umwelt, indem es Emissionen abschneidet und auf natürliche Weise zusammenbricht. Aber, Probleme wie wenige Kompostierungszentren und höhere Preise müssen behoben werden. Die steigende Verwendung zeigt, dass es dazu beitragen kann, eine grünere Zukunft zu schaffen.

Ihr Unternehmen kann einen Unterschied machen, indem Sie PLA -Verpackungen verwenden. Diese Wahl hilft dem Planeten und erfüllt die Kundennachfrage nach grünen Produkten. Verwenden Sie jetzt PLA, um eine sauberere und gesündere Welt zu unterstützen.

FAQ

Was ist Pla, Und warum ist es umweltfreundlich?

PLA, oder Polyltsäure, ist ein Plastik aus Pflanzen wie Mais oder Zuckerrohr. Es ist umweltfreundlich, weil es Treibhausgase senkt, verbraucht weniger Energie, um sie zu machen, und bricht in der industriellen Kompostierung zusammen.

Kann Pla zu Hause kompostiert werden??

Die Kompostierung von PLA zu Hause ist schwer. Es braucht hohe Hitze und besondere Bedingungen, die nur in industriellen Kompostierungszentren zu finden sind. Überprüfen Sie die lokalen Kompostierungsoptionen, um es richtig zu entsorgen.

Tipp: Suchen BPI-zertifizierte Produkte Um sicherzustellen, dass sie kompostiert werden können.

Wie unterscheidet sich PLA von normalen Kunststoffen??

PLA besteht aus Pflanzen und bricht natürlich zusammen, Im Gegensatz zu normalen Kunststoffen aus Öl. Es schafft weniger Treibhausgase, wenn es hergestellt wird, benötigt, benötigt jedoch spezielle Kompostierung und kann nicht mit Wärme umgehen.

Ist PLA sicher für Lebensmittelverpackungen?

Ja, PLA ist sicher für Lebensmittel. Der FDA genehmigt es für Lebensmittelkonsum. Es ist ungiftig und hält Essen frisch, indem es Luft blockiert. Es wird oft für Tassen verwendet, Teller, und Behälter.

Was sind die Hauptprobleme mit PLA?

PLA hat einige Probleme wie teurer zu sein, spezielle Kompostierungszentren benötigen, und nicht Wärme oder Feuchtigkeit gut umgehen. Diese Probleme begrenzen die Verwendung und den Nutzen.

Bricht PLA auf Deponien zusammen??

NEIN, PLA bricht auf Mülldeponien nicht gut zusammen. Es braucht eine hohe Hitze und Feuchtigkeit von der industriellen Kompostierung zu zersetzen. Ohne diese, es kann jahrelang dauern.

Wie können Unternehmen Menschen über die PLA -Entsorgung beibringen??

Unternehmen können klare Anweisungen zur Verpackung hinzufügen. Sie können auch mit Kompostierungszentren zusammenarbeiten und Tipps online teilen, um Menschen bei der richtigen Entsorgung von PLA zu helfen.

Notiz: Menschen beizubringen, wie man PLA entsorgt.

Ist Pla die Kosten für Unternehmen wert?

PLA kostet mehr als normale Kunststoffe, weil es so gemacht wird. Aber seine umweltfreundlichen Funktionen ziehen Kunden an, die sich um den Planeten kümmern, Machen Sie es zu einer klugen Wahl für grüne Marken.

Kontaktieren Sie uns

Denken Sie über die Ziele Ihrer Marke nach, ob PLA zu Ihren umweltfreundlichen Plänen passt.